EMK-800 CNC Trimming and Beading Machines

General Hardware

Continuous improvement is Emin Mekatronik’s mission. We are always looking for ways to improve our CNC skirt cutting machines and offer more value to our customers. We have completely restructured the machine, especially the improvement we have made in the gearbox part of the new generation skirt cutting machine, and implemented many innovations that make it better in the new models. By re-evaluating all aspects of the machine by our engineers, we presented the latest version, which includes mechanical, software and visual improvements, as a package.

Security Light Curtain

With the light barrier placed in front of the work area, the object entering the work area will immediately stop the operation of the machine and prevent possible work accidents.

Rigit Design

Whether a structure is healthy or not is determined by the strength of the construction. The same principle applies to skirt cutting machines. The solidity of the base and the structure of the column determines the machine’s ability to do work. The cast cutting car and the critical cast parts in the renewed reducer group provide higher endurance capacity. All castings are inspected for flex and vibration resistance before and after machining.

High Speed Capability and High Sensitivity

Maximum speed and precision have been achieved with the combination of CAM software developed by our engineers for the Emk-800, high-precision drivetrain and Siemens Motion Control.

Three Axis Cutting Trolley

The cutting trolley, which can rotate 180 degrees, performs skirt cutting and cord pulling (hem strangling) operations without the need for a complex mold. It is generally used in the production of fuel tanks in the automotive industry.

Ergonomic Control Panel

To provide smooth and precise motion control. New generation servo motors are used in EMK-800.

With software enhancements, your machine is faster and more precise than ever before. The built-in USB port makes it possible to use flash memory and external disk drives.

All common functions are clearly labeled on the control panel for easy understanding of the operator, and guidance is performed with the push of a button.

Lubrication System

Thanks to the EMK-800 central lubrication system, it automatically lubricates the places that can be worn by friction at certain intervals. The automatic lubrication system measures the oil while the machine is running and distributes it to the slides and screw shafts. This ensures that all critical elements are always properly lubricated.

The system minimizes the oil problem and reduces the impact on the environment. You can determine the lubrication interval according to the work situation on the interface screen.

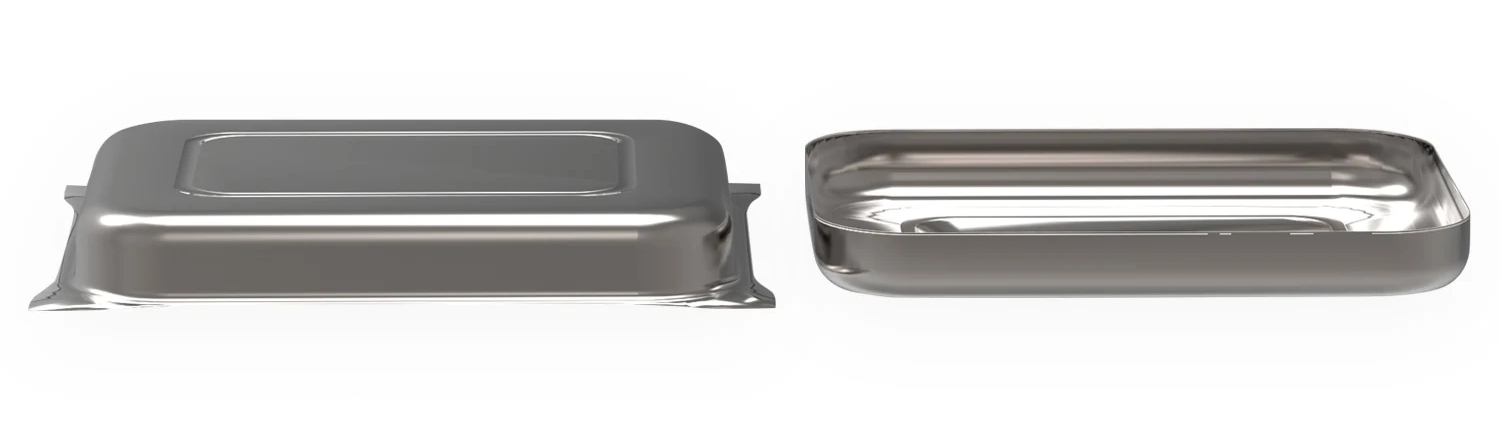

Skirt Cutting and Folding

With the EMK-800, you can easily perform cutting, bending and bending operations on the vertical and horizontal surfaces of the drawn parts.

You can do. You can process many parts used in white goods, automotive, heavy metal and medical industries sensitively and quickly.