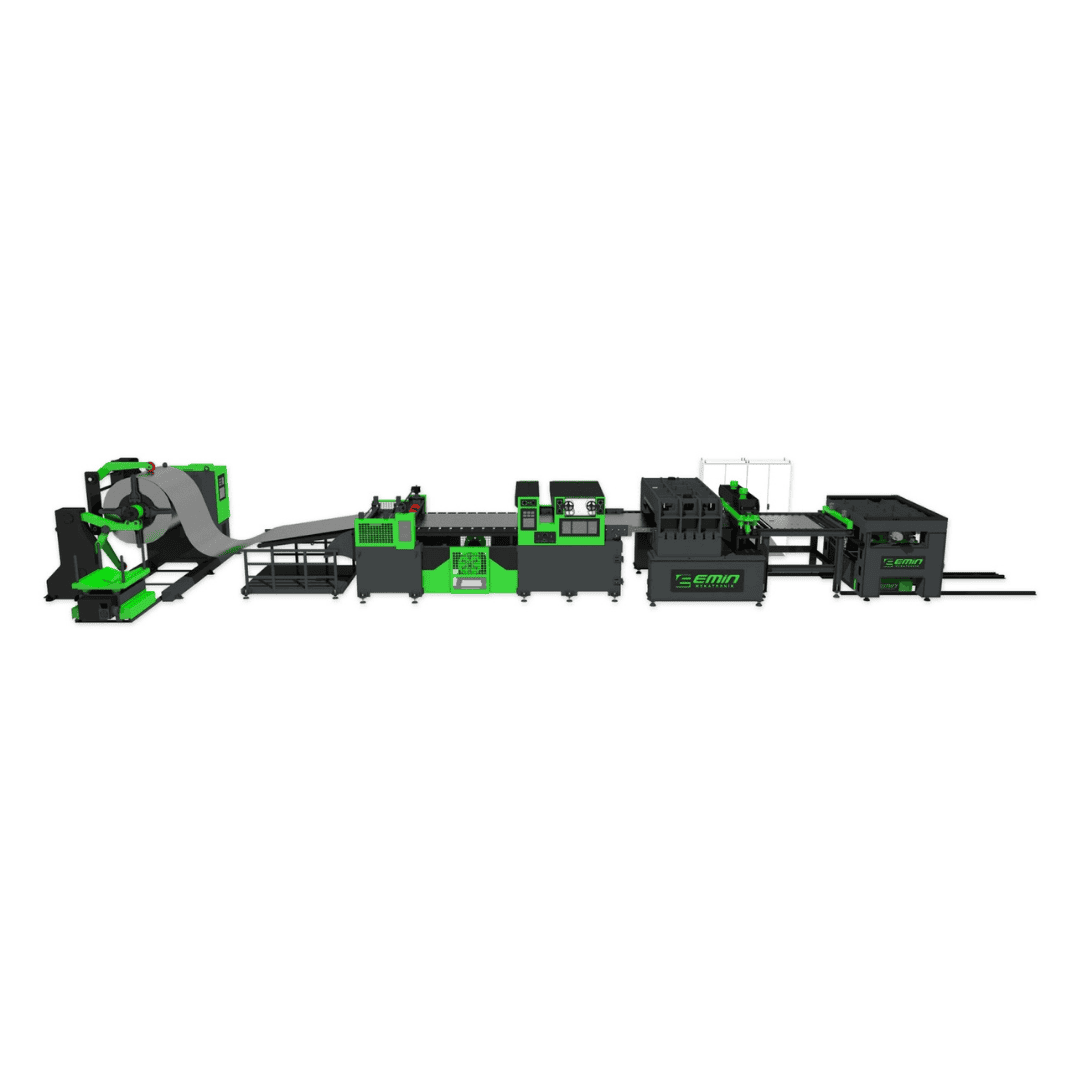

From Coil to Finished Blank in a Single, Continuous Operation

Traditional sheet metal punching, which relies on manually loading individual sheets into a press, is a major bottleneck in modern manufacturing. It’s slow, labor-intensive, and limits production output. Emin Mekatronik’s Automated Sheet Metal Punching Line is the definitive solution, engineered to transform this process by producing perfectly flat, punched, and cut-to-length blanks directly from a raw material coil.

This turnkey system is specially designed for high-volume production, such as the outer body sheets for boilers and tanks, but is versatile enough for a wide range of industrial applications.

The Complete “Coil-to-Blank” Automated Process

Our Roll Punch and Cut-to-Length Line integrates multiple manufacturing stages into one seamless and efficient workflow.

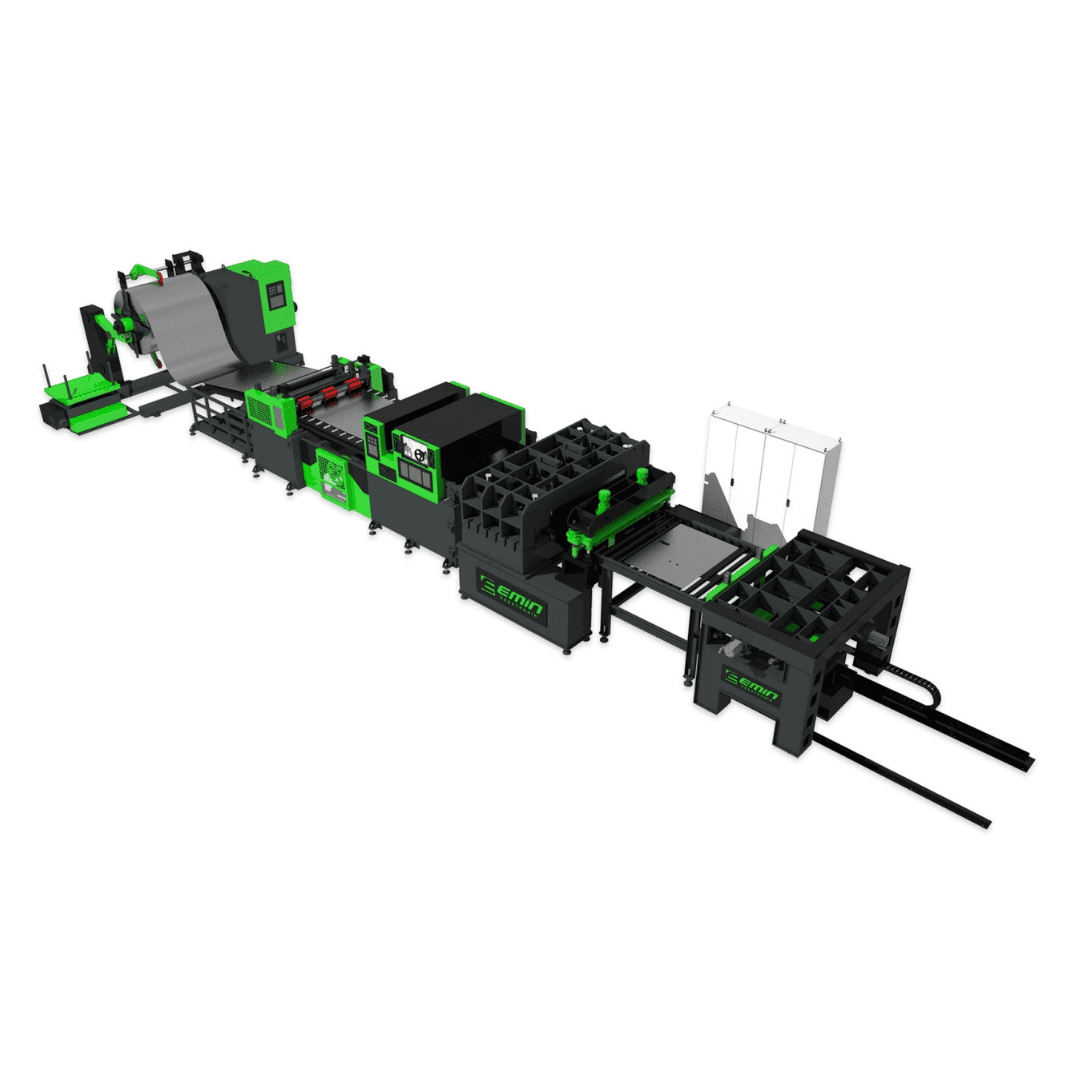

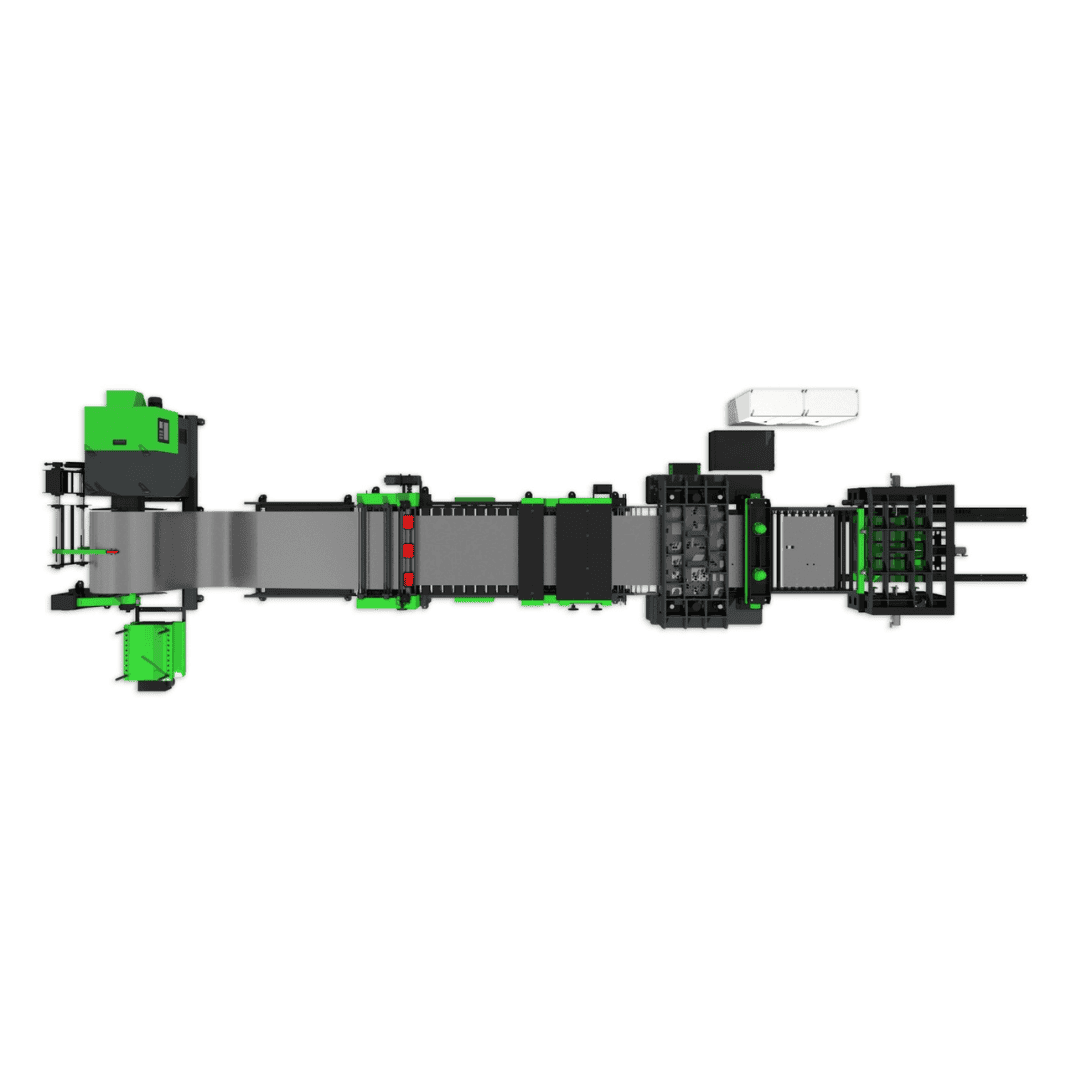

- Uncoiling & Straightening The line begins with a heavy-duty decoiler that securely holds and unrolls the main coil. The sheet metal then passes through a multi-roll precision straightener to remove any coil memory, ensuring the final product is perfectly flat and free of internal stresses.

- Servo Feeding & Integrated Punching A high-speed, high-accuracy servo feeder advances the material into the punching press. Here, the line automatically completes all required optional punching, piercing, and forming operations according to the pre-loaded program, eliminating the need for any secondary press work.

- Optional In-Line Slicing For applications that require various or narrower widths from a single master coil, an optional in-line slitting unit can be integrated to slice the material before the final cut.

- High-Speed Cutting-to-Length Once all punching and processing is complete, a robust and precise hydraulic or mechanical shear cuts the sheet to the exact programmed length with high repeatability.

- Automated Stacking & Packaging The finished, punched blanks are then smoothly transferred via conveyor to an automated stacking unit. This unit creates neat, perfectly aligned stacks, ready for packaging or immediate transfer to the next stage of your production, such as rolling or bending.

Key Features and Strategic Advantages

- Massive Increase in Productivity: By processing directly from a coil, this line eliminates the slow, manual loading of sheets, dramatically increasing throughput.

- Significant Labor Cost Reduction: A fully automated line requires minimal operator intervention, allowing you to re-assign skilled labor to more valuable tasks.

- Superior Accuracy & Quality: The combination of precision straightening and servo feeding guarantees that every blank is perfectly flat, dimensionally accurate, and consistent.

- Lower Raw Material Costs: Purchasing sheet metal in large coils is significantly more cost-effective than buying pre-cut sheets, leading to direct material savings.

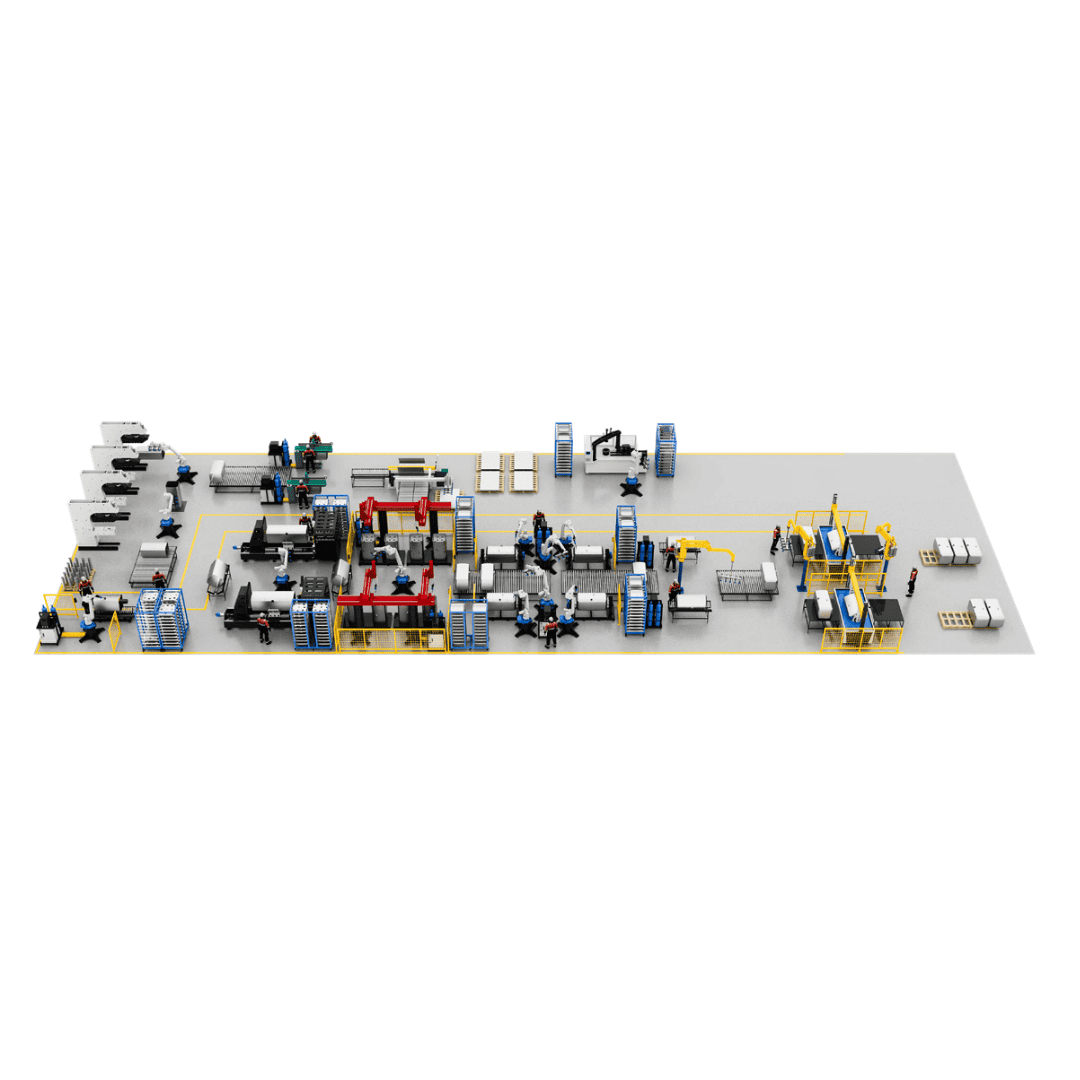

- Full Process Integration: A single, turnkey solution from a trusted partner ensures perfect synchronization between all operational stages.

Primary Applications and Industries

This automated line is the ideal solution for high-volume production in a variety of sectors:

- Boiler, Tank, and Water Heater Outer Casings

- HVAC System Panels and Enclosures

- Metal Cabinets, Shelving, and Lockers

- Electrical Cabinets and Control Boxes

- Appliance Body Panels (e.g., for refrigerators, ovens)

Replace your inefficient, multi-step processes with a single, high-speed automated solution. To learn how our Automated Sheet Metal Punching Line can transform your production, contact our engineering team for a detailed consultation and proposal.