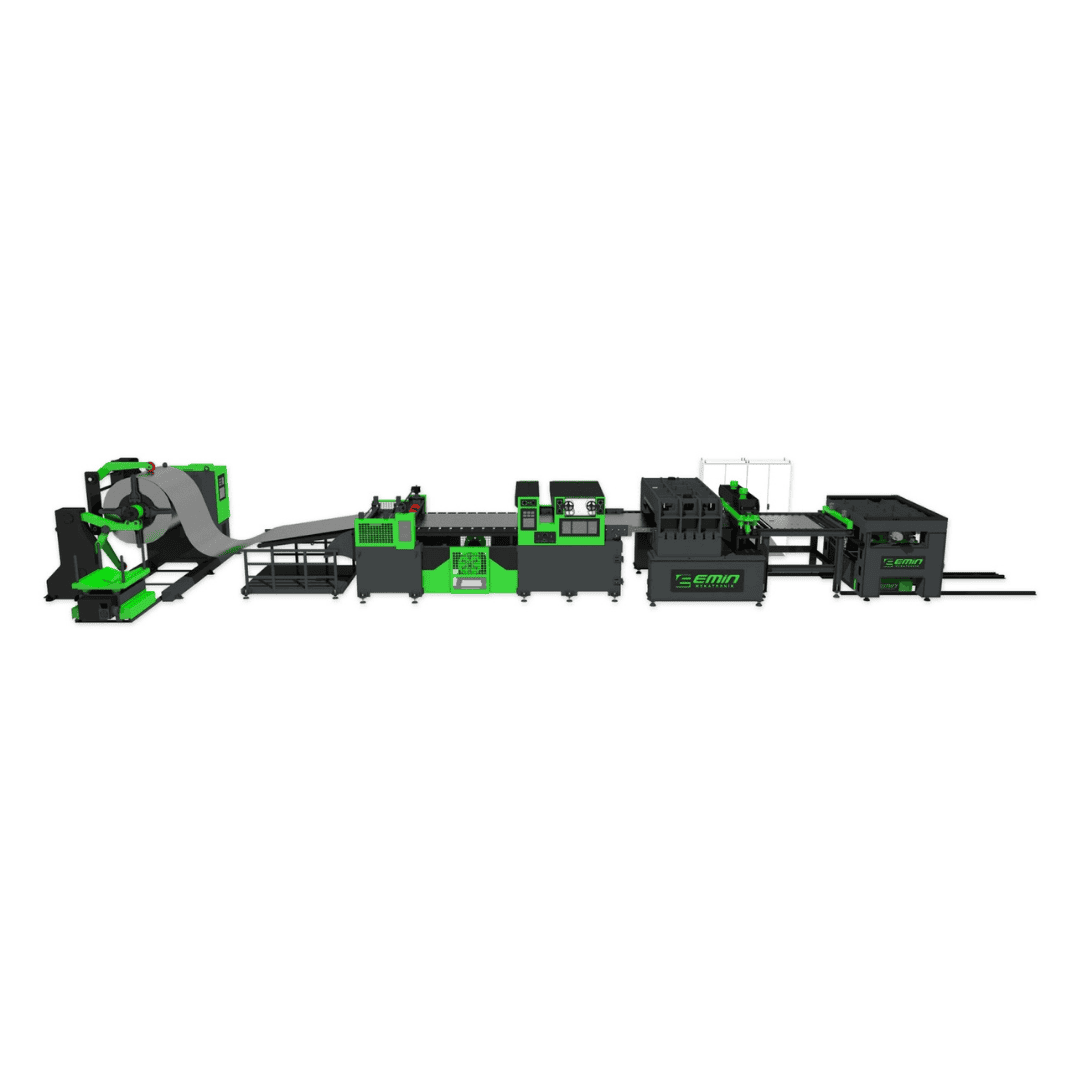

Dished Head Production Line for Hot Water Buffer Vessels and Tanks

From Coil to Finished Product: A Fully Automatic and Integrated Solution

The quality of manufacturing boilers, water heaters, and pressure vessels depends on the flawless and consistent production of their core components: the dished heads. Traditional, multi-stage production processes (separate cutting, pressing, and edge-trimming stations) can be slow, labor-intensive, and prone to inconsistency.

Emin Mekatronik’s Dished Head Production Line is a fully integrated and automatic solution designed to overcome these challenges. We offer a “coil-to-part” turnkey system that transforms coiled sheet metal into finished, trimmed, and assembly-ready dished heads in a single, continuous operation.

A Fully Automatic, Single-Operation Process

Our production line is not designed as a collection of separate machines but as a single, synchronized system. This turnkey approach automates the entire manufacturing process, providing significant improvements in speed, quality, and operational costs.

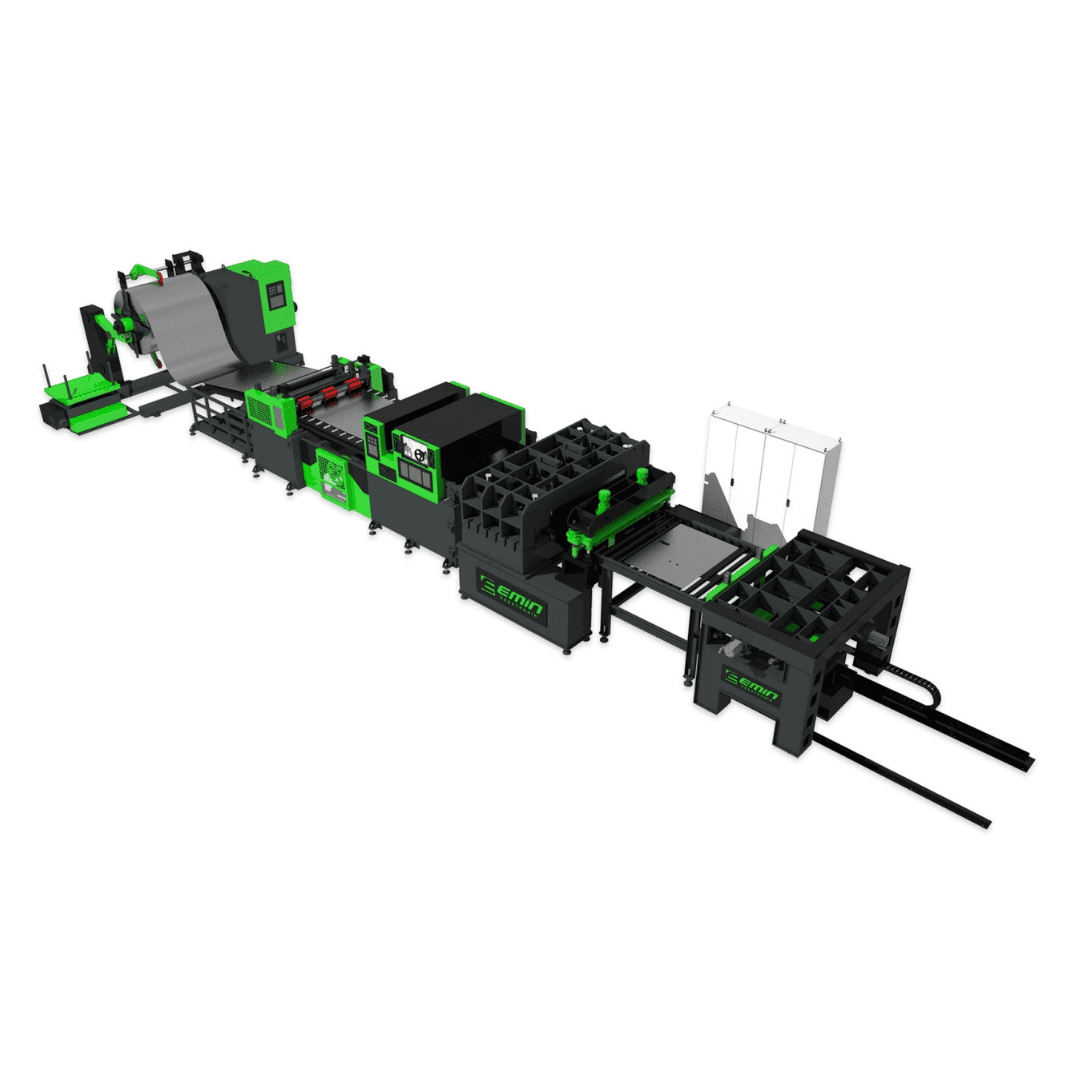

- Coil Decoiling and Feeding: The process begins with the automatic and precise feeding of coiled sheet metal into the line.

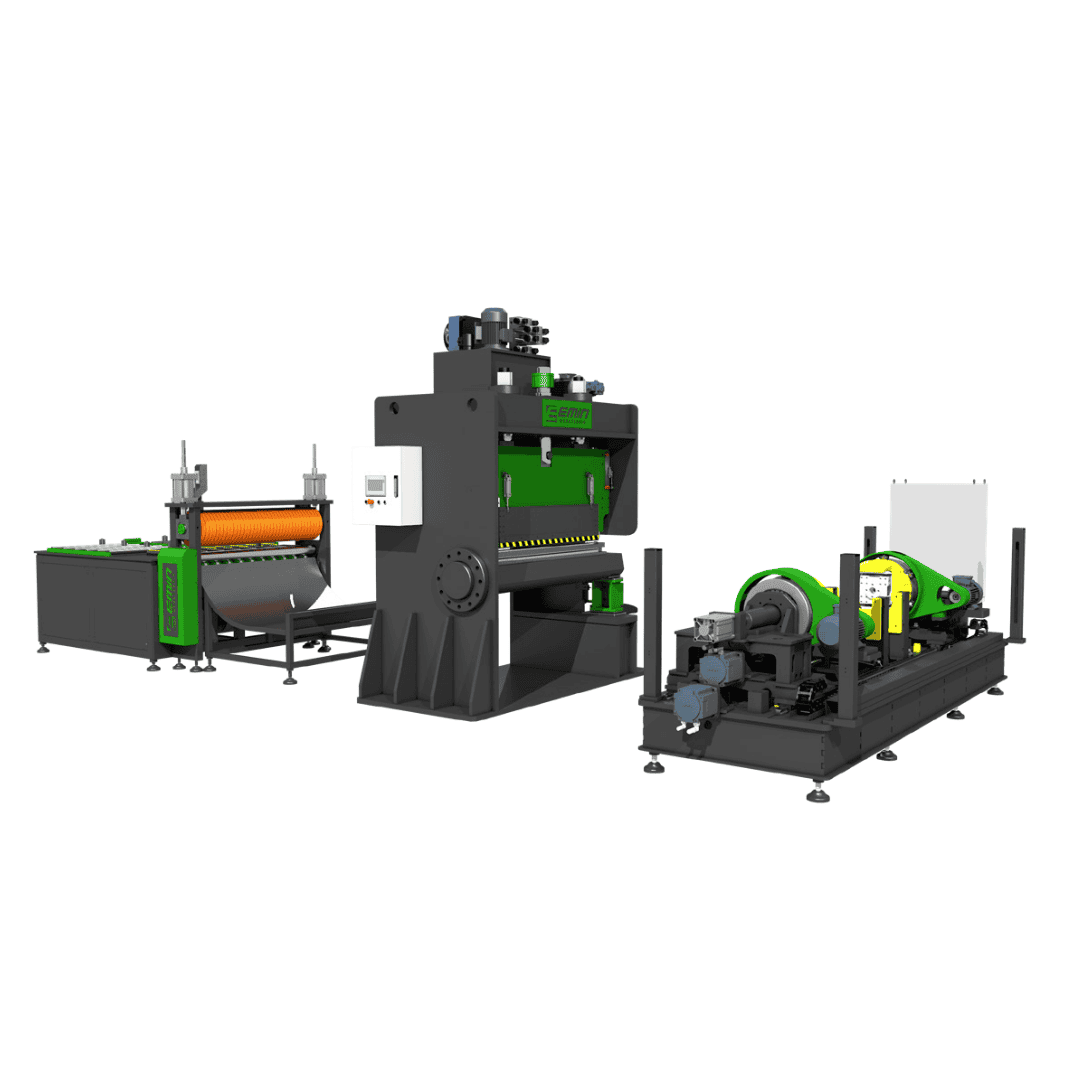

- Circle Cutting (Blanking): In the first operational stage, a high-precision die cuts the sheet metal into a perfect circular form (blank), optimized to minimize material scrap.

- Deep Drawing: The seamlessly transferred circular blank then enters the high-tonnage deep drawing press, where it is formed into its final “dished head” geometry.

- Edge Trimming: The formed part moves to an integrated trimming station where the excess edge material (skirt) is precisely cut to its final dimensions.

- Programmable Hole Punching (Optional): A revolutionary feature of our line is the ability to program holes on the dished head (e.g., for heating elements or anode rods) directly from the operator panel. This function offers the flexibility to switch instantly between models with or without holes, requiring no mechanical adjustments or secondary operations.

- Automatic Part and Scrap Ejection: The completed, finished dished head and the resulting scrap are automatically ejected from the line, ready for the next assembly stage.

Key Features and Strategic Advantages

- Increased Efficiency: By combining multiple operations into a single continuous process, the line significantly reduces cycle times and increases production output.

- High Quality and Consistency: The automated process eliminates human error, ensuring every dished head is dimensionally identical and meets the highest quality standards.

- Reduced Labor Costs: Requires minimal operator supervision, freeing up your skilled workforce for more complex tasks.

- Superior Production Flexibility: The programmable hole-punching feature allows you to switch instantly and cost-effectively between product models that require holes and those that do not.

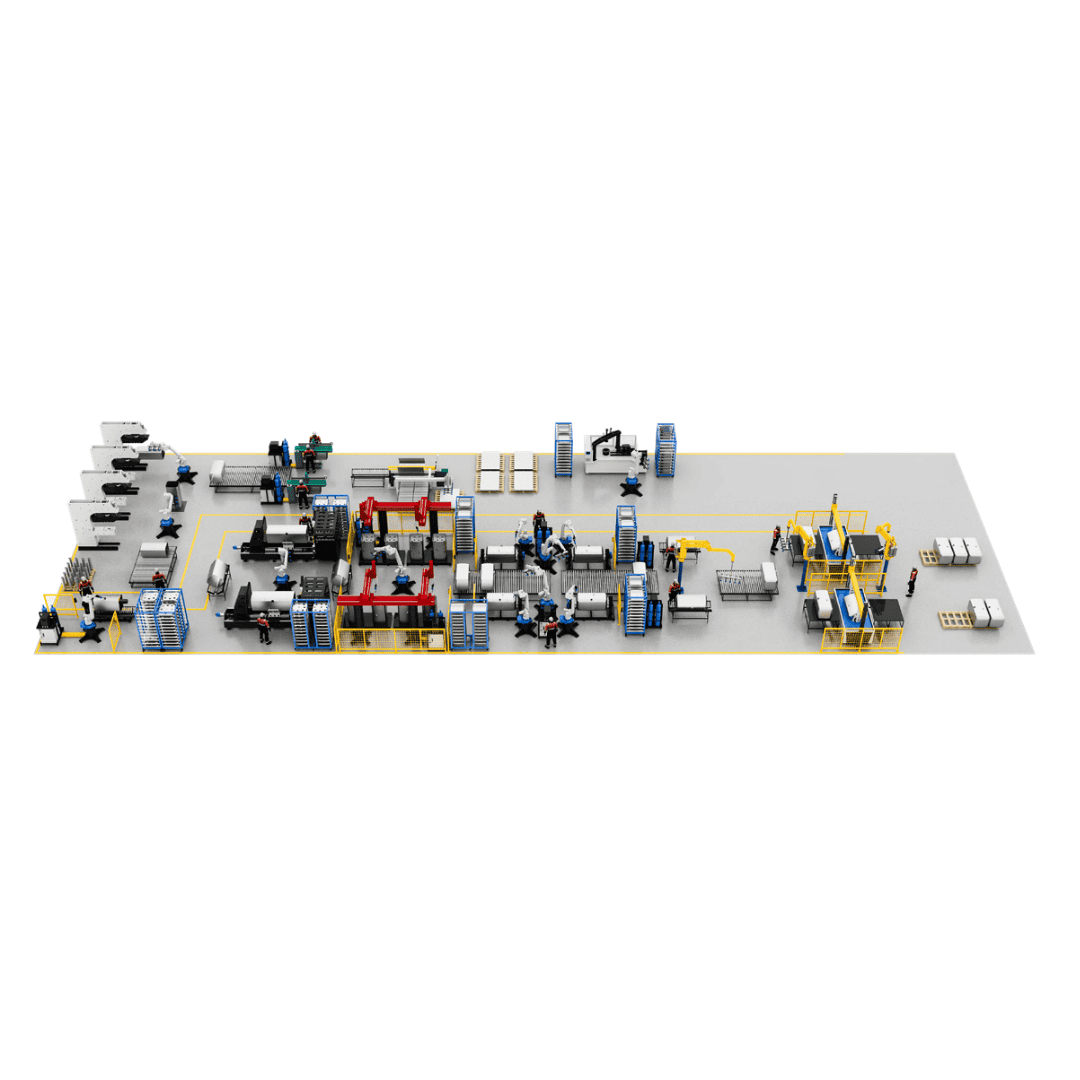

- Ideal Applications

This production line is the perfect manufacturing solution for producers of the following products:

- Electric Water Heaters

- Hot Water Boilers

- Accumulation and Buffer Tanks

- Solar Water Heating Systems

- Small-Scale Pressure Vessels

Modernize your manufacturing process with automation. Contact our system engineering team today to receive a custom production line proposal and detailed technical information.