Custom Design Forming Machines

Custom Design Forming Machines

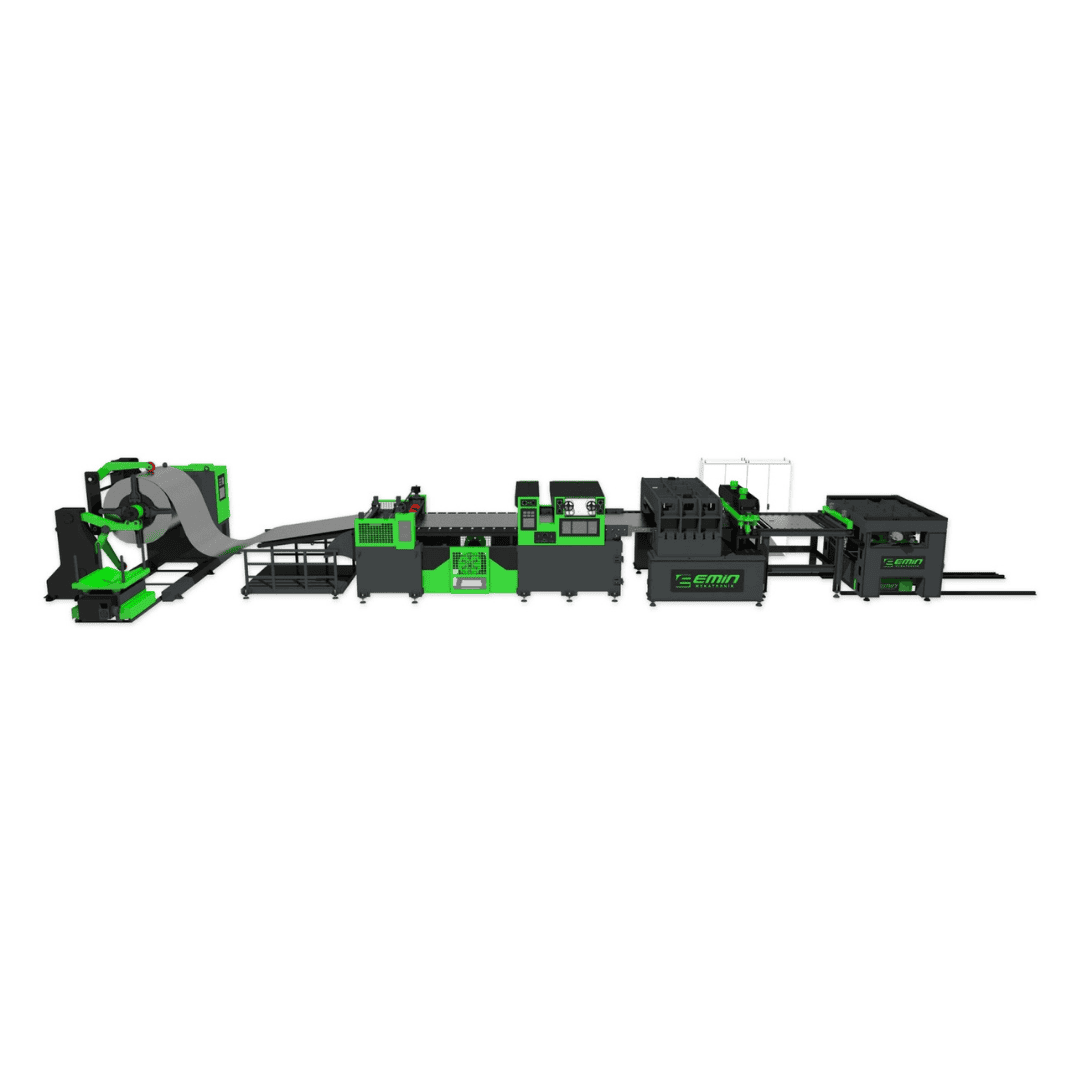

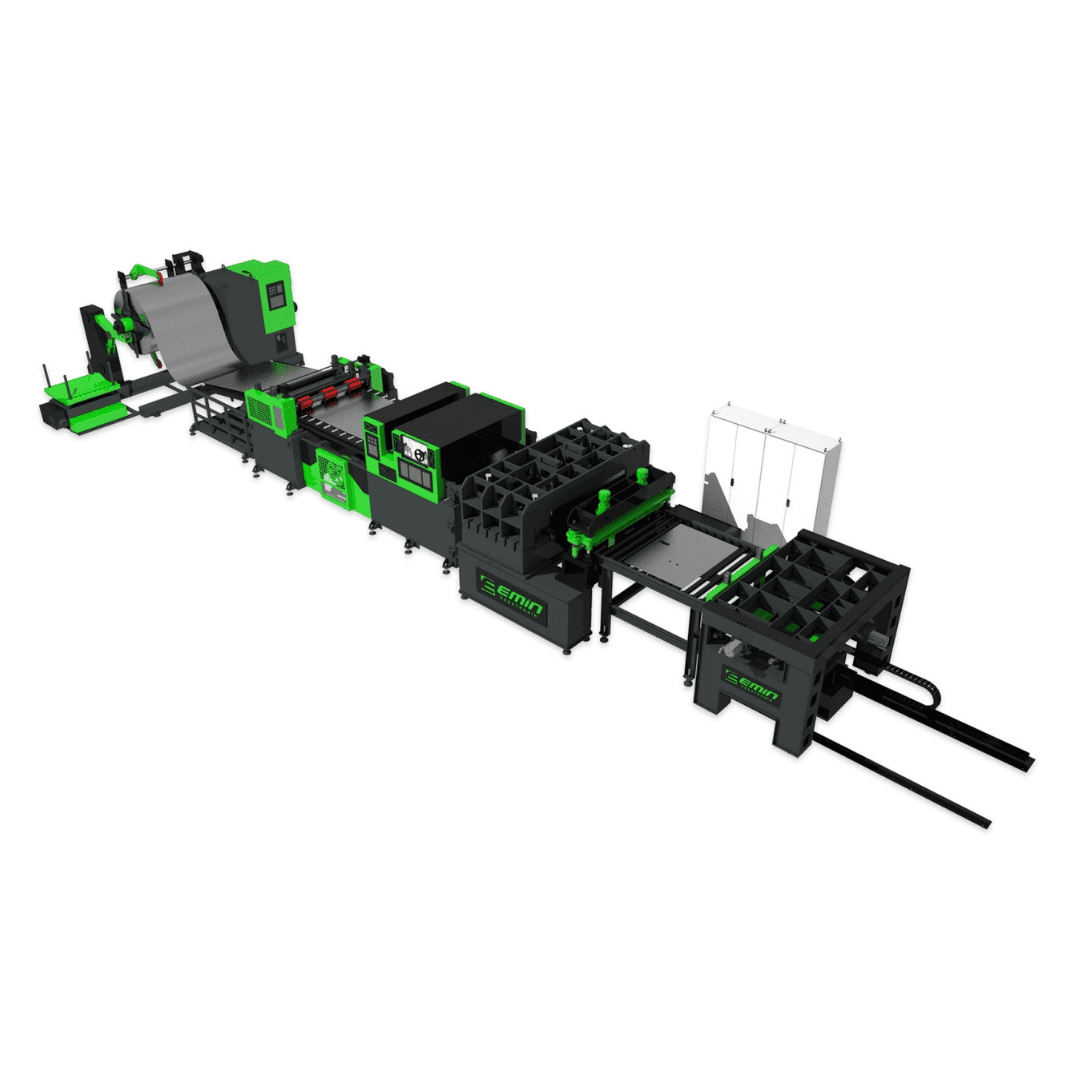

Dished Head Production Line for Hot Water Buffer Vessels and Tanks

Industrial Automation & Mechatronics

In the contemporary era of manufacturing, a machine without intelligence is merely a collection of moving metal parts. Emin Mekatronik was founded on the principle that true industrial efficiency arises only from the seamless fusion of mechanical engineering and electronic control—a discipline known as Mechatronics. Since 2009, our Industrial Automation & Mechatronics division has been the driving force behind every turnkey plant we commission. We do not just build the body of the machine; we engineer its nervous system and its brain.

For the global investor or factory manager, automation is not a luxury; it is a prerequisite for survival. It is the only rational path to achieving consistent quality, reducing reliance on manual labor, and maximizing Overall Equipment Effectiveness (OEE). By integrating world-class Siemens control architectures into our systems, we provide robust, scalable, and future-proof solutions. To understand how this core competency shapes our entire business model, we invite you to read our corporate story on our About Us page.

The Synergy of Mechanics and Electronics

The term "Turnkey Solution" is often misused in the industry. For many, it simply means buying a machine and a robot from different vendors and hoping they work together. At Emin Mekatronik, we take a radically different approach. Our mechanical designers and automation engineers work in the same open office, collaborating from the very first concept sketch.

This integrated workflow ensures that the mechanical dynamics of a Fuel Tank Production Line are perfectly matched to the servo motor capabilities selected by the automation team. We do not force software to fix mechanical flaws; we design mechanics that are inherently optimized for automation. This results in smoother motion profiles, lower energy consumption, and significantly extended machine life.

Siemens: The Global Standard in Control

In industrial automation, reliability is the currency of trust. That is why we have standardized our platforms on Siemens Automation Technology. We are not just users; we are experts in the Siemens ecosystem, including:

- Simatic S7 PLCs: The robust logic controllers that manage complex sequences with millisecond precision.

- Sinamics Drives: High-performance servo drives that control speed and torque, essential for the precision required in our EMK Series forming machines.

- Sinumerik CNC: The industry gold standard for multi-axis interpolation, which powers our complex metal forming operations.

- WinCC SCADA/HMI: Intuitive interfaces that visualize production data, allowing operators to control complex processes with minimal training.

By adhering to this global standard, we ensure that our clients anywhere in the world have access to spare parts and technical support, eliminating the risk of proprietary "black box" systems.

Motion Control: The Art of Precision

Automation is fundamentally about moving things—precisely, quickly, and repeatedly. Our expertise in Motion Control is evident in our high-speed applications. Whether it is synchronizing the feed rate of a coil in a Sheet Metal Punching Line or coordinating the multi-axis movement of a robotic arm, we utilize advanced kinematics.

We implement "Electronic Camming" and synchronized gearing profiles in software, replacing wear-prone mechanical cams and gears. This not only reduces maintenance but allows for instant product changeovers via the HMI panel, a critical feature for high-mix manufacturing environments.

Safety Integration (Sil 3 / PLe)

In an automated environment, safety is non-negotiable. We adhere strictly to European CE Safety Standards. Our automation architecture includes integrated Safety PLCs and Safe Torque Off (STO) drive functions.

This means that if a light curtain is breached or an E-Stop is pressed, the system brings high-inertia loads to a controlled stop immediately, protecting both the operator and the tooling. This level of safety integration is standard across all our lines, from simple presses to complex Dished Head Production Lines.

Industry 4.0 and Digital Transformation

We are moving from the era of automated machines to the era of connected systems. Emin Mekatronik builds machines that are Industry 4.0 Ready. Through protocols like OPC-UA and Profinet, our machines can communicate vertically with your factory's ERP or MES systems.

- Real-Time Monitoring: Track cycle counts, uptime, and fault history remotely.

- Predictive Maintenance: Analyze motor current draw and vibration data to predict component failure before it stops the line.

- Remote Diagnostics: Our Service team can securely tunnel into the machine's PLC to diagnose code issues or optimize parameters without needing to fly an engineer to your site.

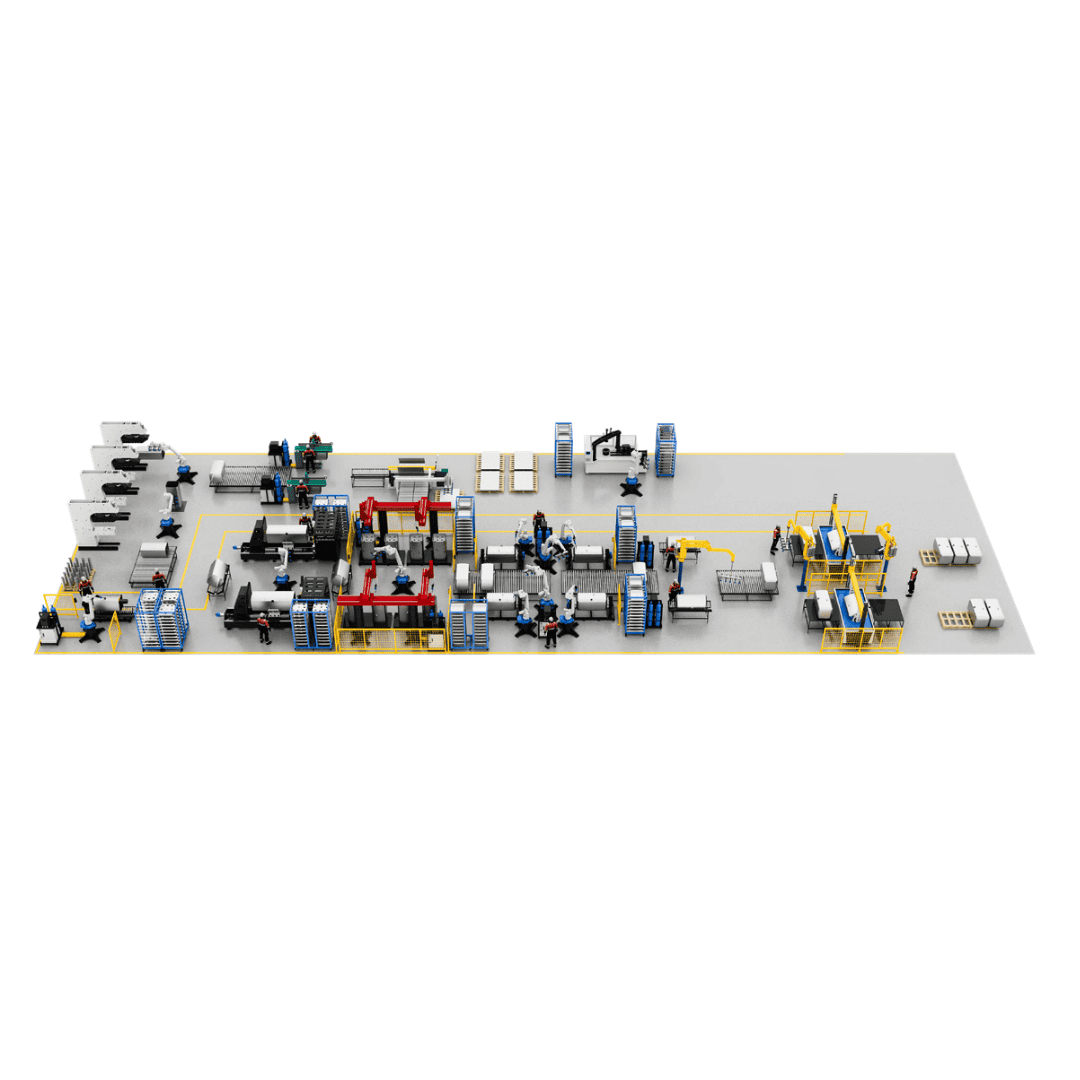

Robotic Integration and Handling

While we manufacture the core forming machinery, complete automation often requires robotic handling. We act as master integrators, seamlessly marrying 6-axis industrial robots (Kuka, ABB, Fanuc) with our production lines.

For example, in a Water Heater Casing Line, robots are used for picking blanks, transferring parts between forming stations, and palletizing finished goods. Our automation engineers handle the complex "handshaking" signals between the robot controller and the machine PLC, ensuring a collision-free and fluid operation.

Custom Automation Challenges

Standard automation solutions often fail when faced with unique product geometries or unconventional processes. This is where our Custom Mechatronics capability shines. We design bespoke automation cells for niche applications.

A prime example is our EMK-850 Traffic Sign Machine. We developed a custom algorithm to synchronize the cutting and beading of non-circular shapes, a task that standard CNC controllers struggle to handle efficiently. If you have a process that "can't be automated," we invite you to challenge our engineering team.

Retrofitting and Modernization

Automation expertise is not limited to new machines. We also offer Retrofitting Services for your existing legacy equipment. We can strip out obsolete relay logic or old proprietary controllers and replace them with modern Siemens PLCs and servo systems. This revitalizes old iron, giving it the precision and connectivity of a brand-new machine at a fraction of the cost.

The Emin Mekatronik Advantage

Why choose Emin Mekatronik for your automation needs?

- In-House Coding: We write 100% of our PLC and HMI code in-house. We do not rely on third-party contractors, ensuring we have full control over the logic and can support it indefinitely.

- Process Knowledge: We are process engineers first. We understand the physics of Cutting and Forming Dies, so we program our automation to treat the tooling gently, extending its life.

- Global Experience: Our systems are running in diverse environments worldwide. Check Our References to see the global reach of our technology.

Automation is the lever that multiplies your production capacity. Whether you need a single automated cell or a fully integrated factory, we have the mechatronic expertise to deliver it. Explore our technical capabilities in our Digital Catalog.

Do not let outdated controls hold back your production potential. Contact our Automation Engineers today for a comprehensive analysis of your manufacturing needs.