Production Lines

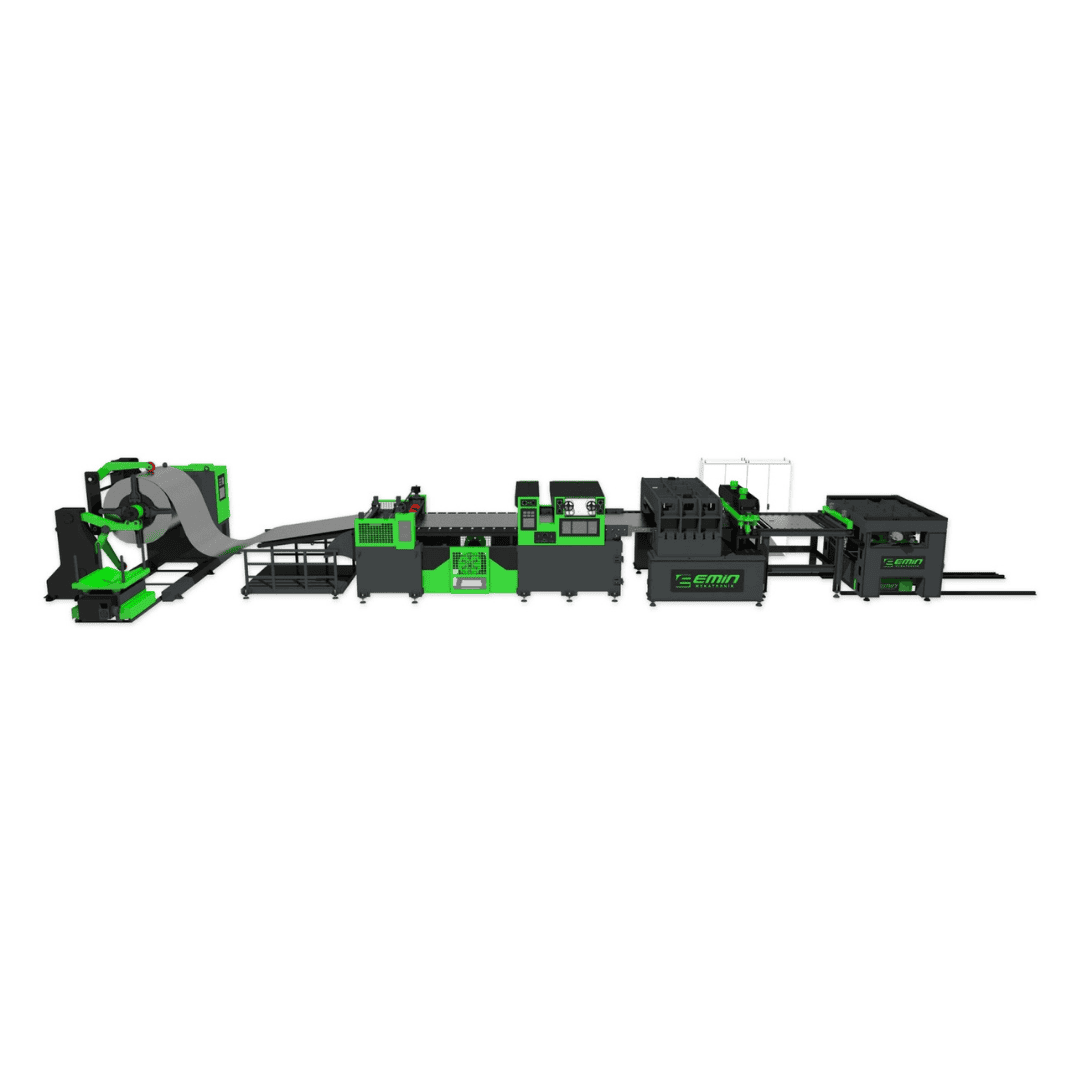

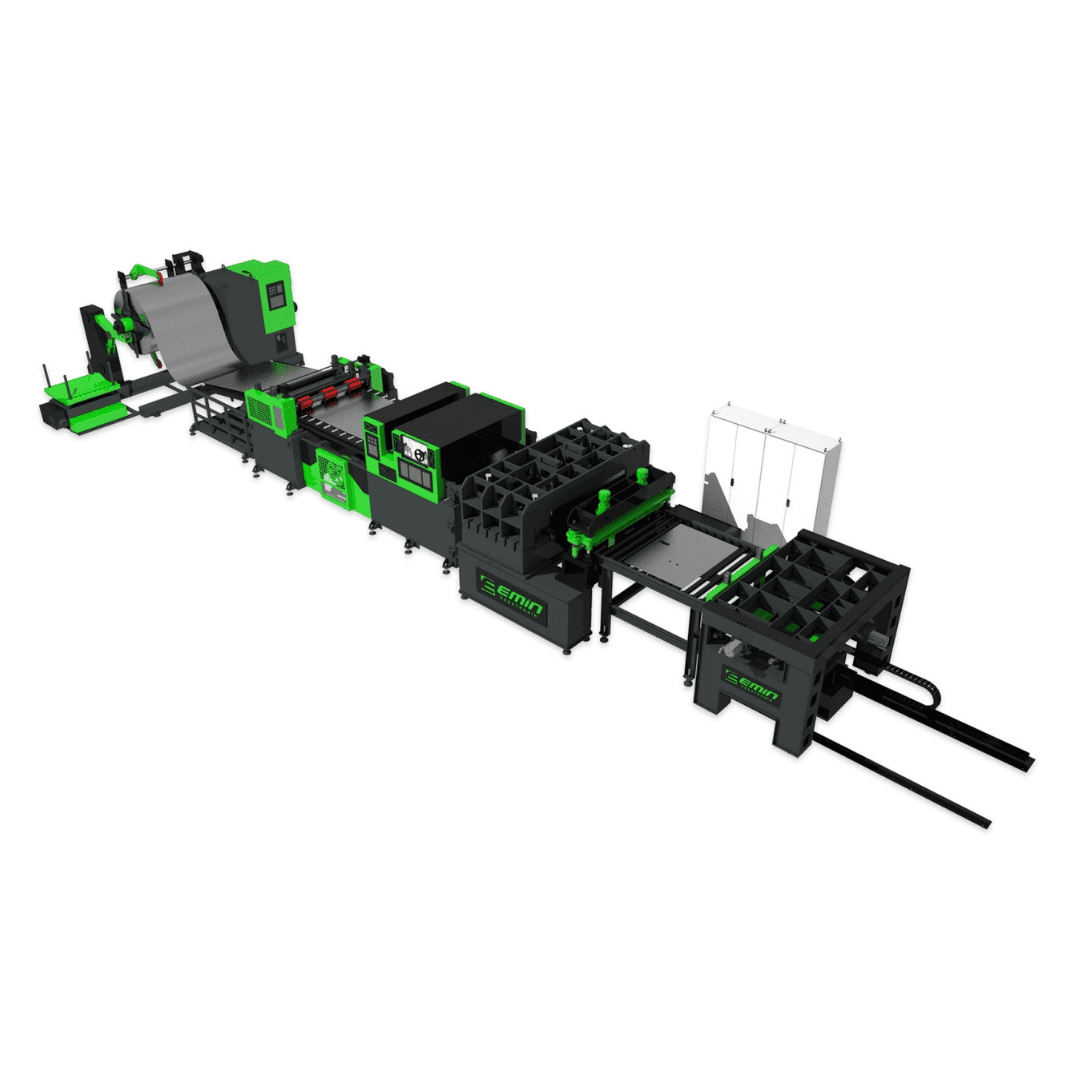

Sheet Metal Casing Line for Hot Water Buffer Vessels and Tanks

In the competitive arena of modern manufacturing, the transition from batch processing to continuous production is the defining factor of market leadership. Emin Mekatronik establishes this transition through our advanced Roll Forming Production Lines. Since 2009, we have engineered systems that transform coiled sheet metal into complex, high-precision profiles in a single, uninterrupted pass. This category represents the pinnacle of "Cold Forming" engineering, where high-speed throughput meets micron-level dimensional accuracy.

Unlike traditional brake press bending, which is limited by the "stop-and-go" nature of the operation and the skill of the operator, our roll forming lines are automated ecosystems designed for volume. We treat the metal not as a static object, but as a dynamic flow. By calculating the material's yield strength, elasticity, and spring-back characteristics, we build lines that deliver consistent quality, meter after meter, day after day. To understand the depth of our engineering heritage, we invite you to review our operational philosophy on our About Us page.

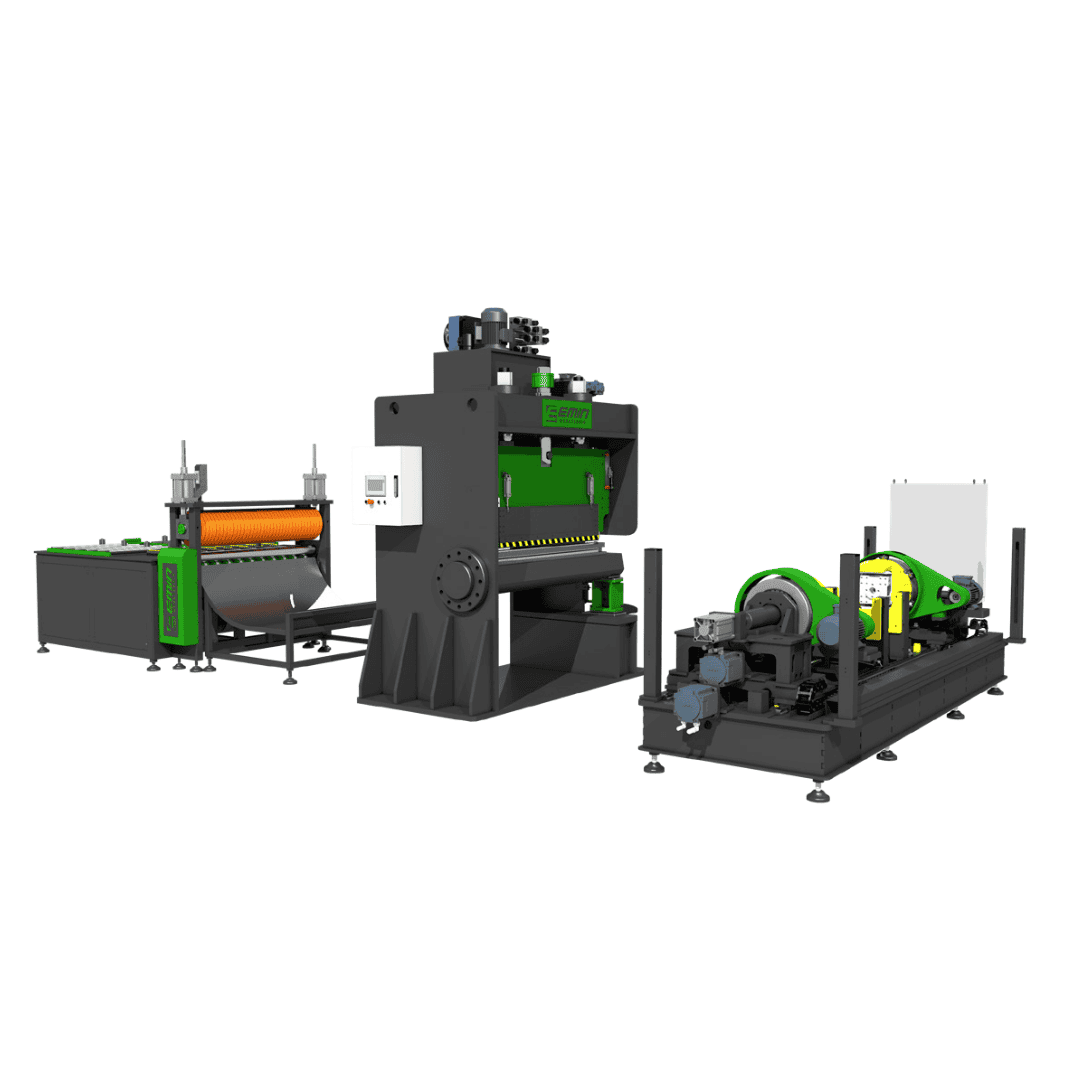

The Physics of Continuous Profiling

A roll forming line is a complex exercise in applied physics. The strip of metal passes through a series of mating roller dies, each station incrementally bending the material until the final geometry is achieved. The success of this process depends entirely on the design of the "Flower Pattern"—the sequential unfolding of the bending steps.

At Emin Mekatronik, we utilize advanced simulation software (COPRA) to validate these patterns before a single piece of steel is cut. This allows us to predict and neutralize defects such as edge wave, bow, or twist. Whether your profile requires simple angles or complex open/closed sections with hemmed edges, our engineering ensures stress-free forming. This meticulous approach is what separates a standard machine builder from a process engineering partner.

Inline Process Integration: The Turnkey Advantage

Efficiency in roll forming comes from integration. A standalone rolling machine is often insufficient for modern production needs. We engineer complete turnkey lines that integrate multiple processes into a single workflow:

- Pre-Punching & Notching: Many profiles require holes, slots, or embossed features. We integrate high-speed servo feeders and presses at the start of the line. This technology mirrors our standalone Automated Sheet Metal Punching Lines, ensuring that the hole pattern is perfectly synchronized with the rolling speed.

- Inline Welding: For closed profiles (like tubes or structural beams), we can integrate high-frequency induction or laser welding stations directly into the roll former.

- Flying Cut-Off: Stopping the line to cut the profile kills efficiency. We implement "Flying Shear" technology, where the cutting die accelerates to match the line speed, cutting the profile while it is in motion. This results in zero downtime and maximizes Overall Equipment Effectiveness (OEE).

Custom Solutions for Niche Applications

While standard profiles (like C or U channels) are common, Emin Mekatronik excels in the "Custom" and "Difficult." We have developed specialized lines for unique industrial applications:

HVAC and Appliance Casing

In the white goods and heating sector, aesthetics are as important as structure. Our Sheet Metal Casing Lines for water heaters utilize roll forming principles to create the outer jacket of the boiler. These lines handle pre-painted material with extreme care, using polished or chromed rollers to ensure no surface scratches occur during the forming process.

Automotive and Structural Components

For the automotive industry, where high-tensile steels are used for crash protection components, we design heavy-duty lines capable of exerting immense forming pressure. The tooling for these lines is derived from our deep expertise in Cutting and Forming Dies, ensuring the rolls have the requisite hardness and toughness to withstand millions of cycles.

The Flexibility Challenge: Cassette Systems

A common criticism of roll forming is its lack of flexibility. We have solved this with our Quick-Change Cassette Systems. In a traditional setup, changing the rolls for a different profile could take a full shift. With our cassette design, the entire set of tooling stands (shafts and rolls) is mounted on a sub-plate.

When a product changeover is needed, the operator simply disconnects the drive coupling and lifts the entire cassette out, replacing it with the new profile setup. This reduces changeover time from hours to minutes, making roll forming viable even for medium-sized production batches.

Automation and Siemens Control

Controlling a line that moves at 60 meters per minute requires a robust "brain." We standardize on Siemens Simotion and S7 PLCs for all our roll forming lines. This provides:

- Precise Synchronization: The punch, the roll former drive, and the flying shear must remain perfectly synced. If the line speeds up or slows down, the hole pitch must remain constant. Siemens Motion Control handles this complex interpolation effortlessly.

- Recipe Management: Operators can save hundreds of profile definitions (length, quantity, hole pattern) in the HMI.

- Remote Diagnostics: Our Service team can remotely access the line to optimize loop control parameters or troubleshoot drive faults, ensuring global uptime.

Tooling Material and Lifespan

The rollers are the only part of the machine that touches your product. Their quality dictates the quality of your profile. We manufacture our rollers in-house using high-grade tool steels (like D2 or 1.2379), which are heat-treated and precision ground.

For demanding applications, such as processing abrasive materials or stainless steel, we apply specialized surface coatings (TiN, CrN) to reduce friction and prevent galling. This attention to Die Material Science ensures that the profile dimensions remain within tolerance for the lifespan of the tooling.

Why Invest in an Emin Mekatronik Roll Former?

Purchasing a roll forming line is a significant capital investment. Partnering with Emin Mekatronik mitigates the risk through our comprehensive turnkey approach:

- Feasibility Analysis: We don't just quote a machine; we analyze your profile drawing to determine the optimal number of stations and the most cost-effective strip width.

- In-House Manufacturing: From the machine frame to the complex punching dies, we control the entire supply chain.

- Global Standards: All lines are built to CE safety standards, utilizing safety PLCs and interlocked guarding to protect your workforce.

Whether you are producing solar mounting struts, shelf uprights, or complex automotive trims, our technology scales to meet your needs. We invite you to explore our capabilities in our Digital Catalog or view our successful installations on Our References page.

Move from batch manufacturing to continuous efficiency. Contact our Engineering Team today for a detailed profile analysis and a custom line proposal.