Custom Design Forming Machines

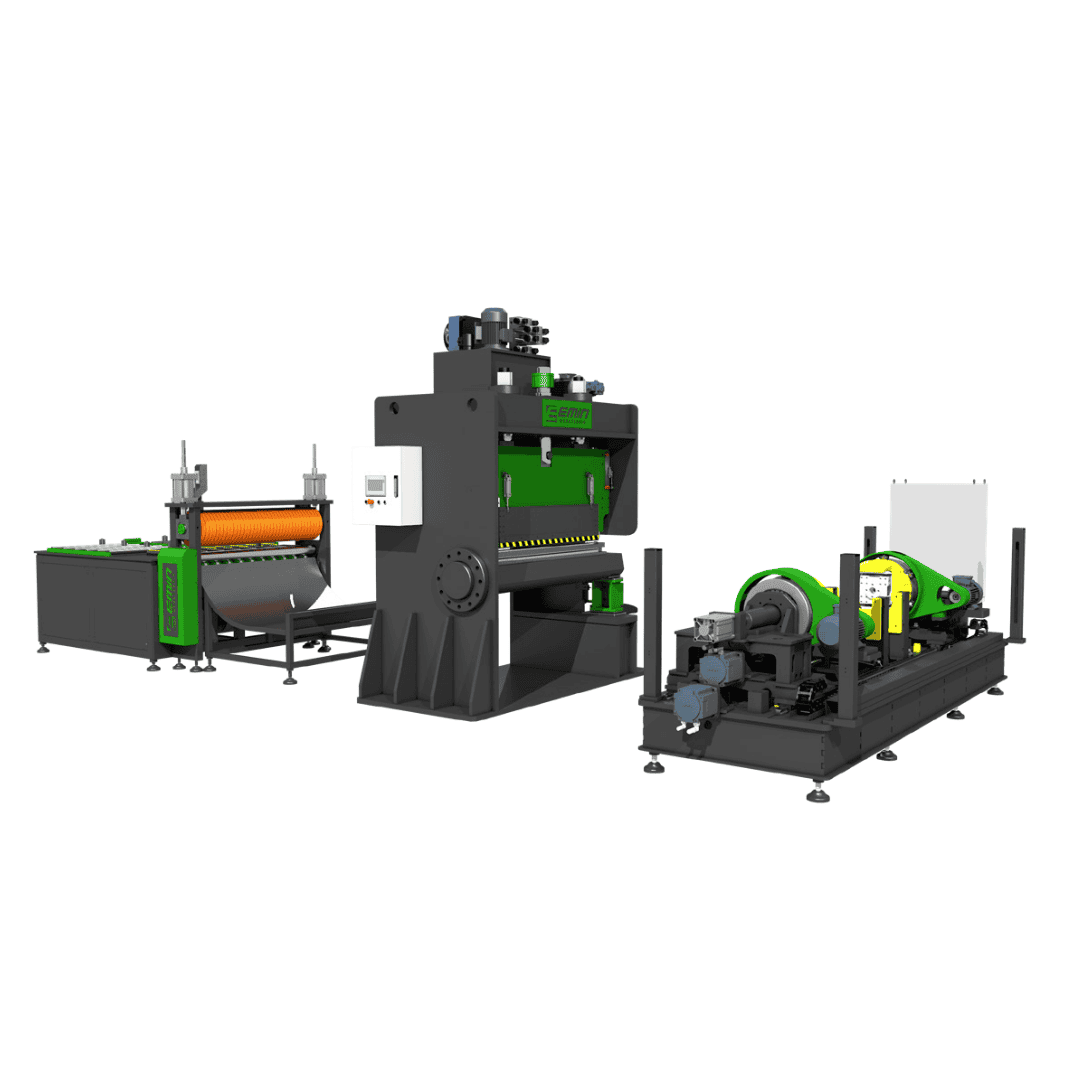

Dished Head Production Line for Hot Water Buffer Vessels and Tanks

Industrial Automation & Mechatronics

Production Lines

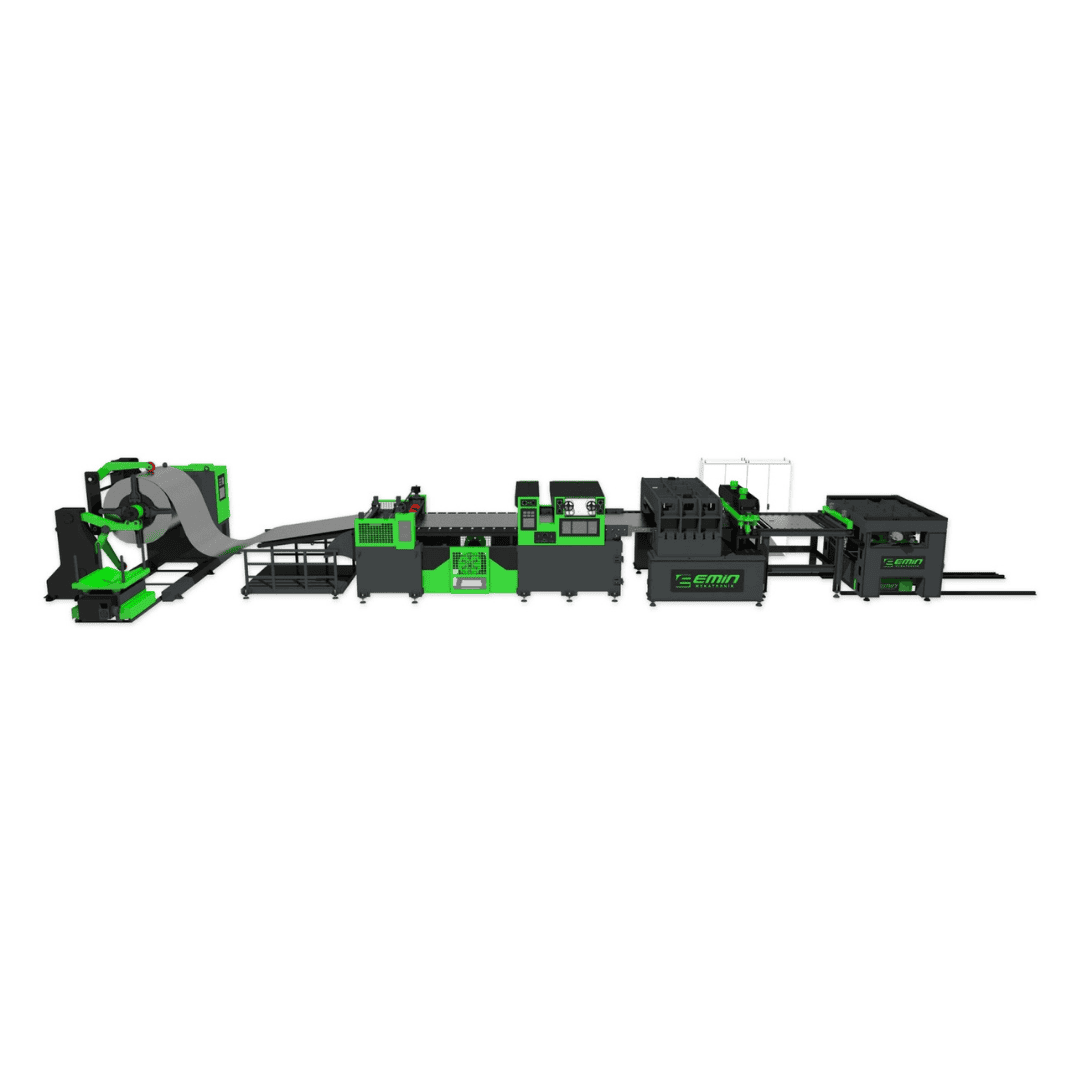

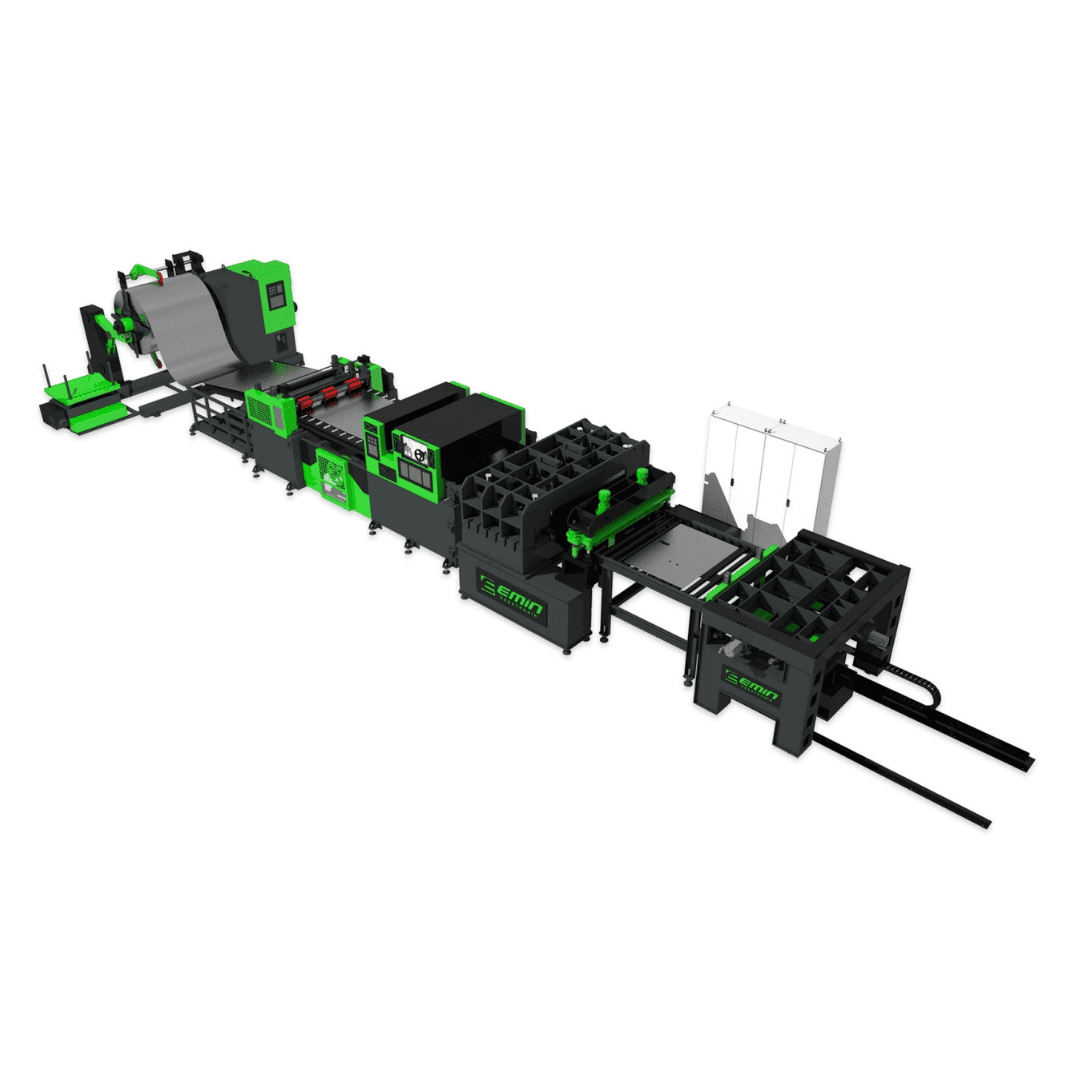

Sheet Metal Casing Line for Hot Water Buffer Vessels and Tanks

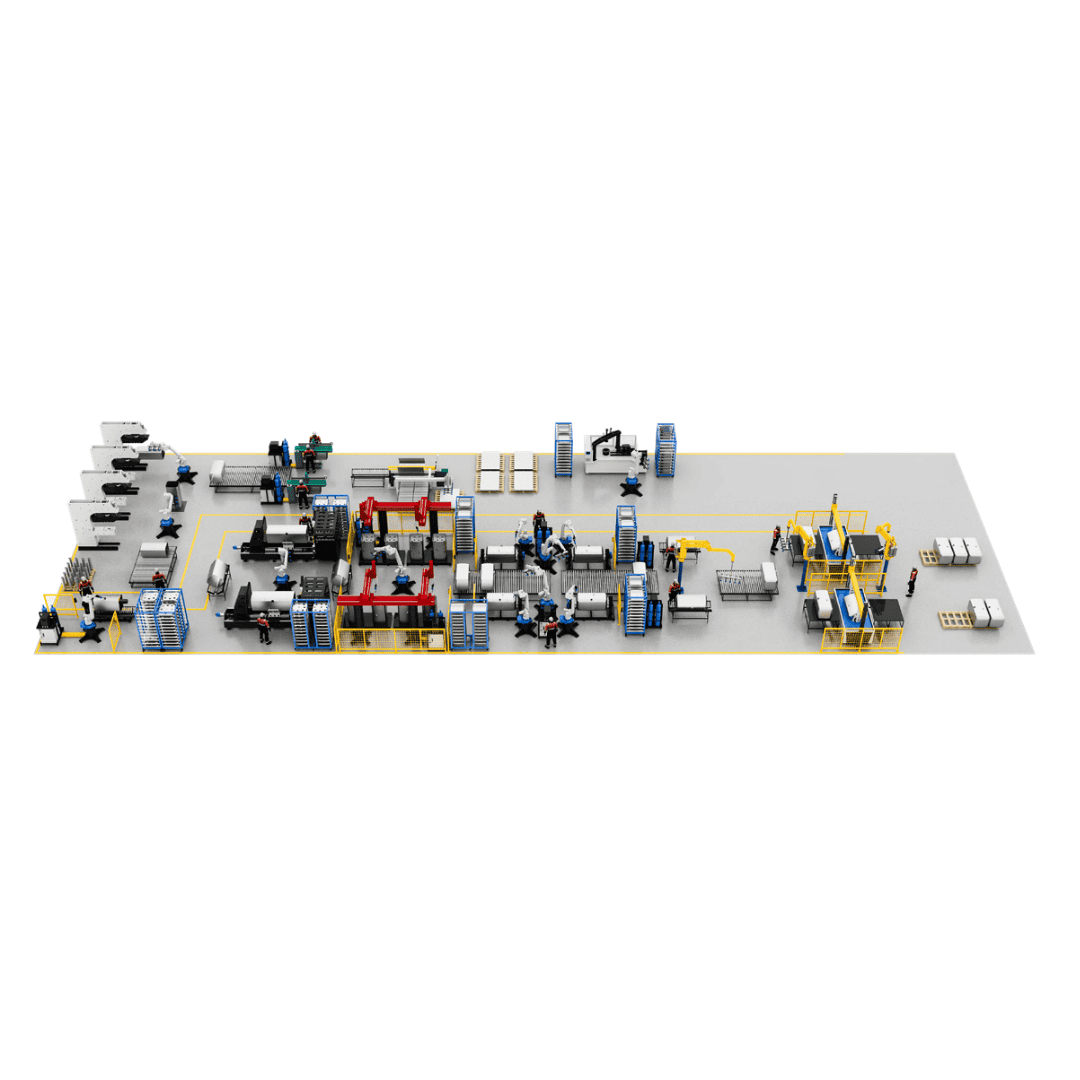

Since 2009, at Emin Mekatronik, we have evolved beyond manufacturing standalone machines to engineering turnkey industrial production facilities. This category represents our holistic approach to manufacturing, where we treat the entire process—from raw material intake to final product assembly—as a unified engineering challenge. With over 15 years of experience, we provide the automation power and efficiency your factory needs from a single source.

Strategically, we eliminate the integration risks associated with managing multiple vendors. By choosing us, you ensure that your machinery, molds, and software operate in flawless harmony. To understand our corporate philosophy and engineering heritage, you can review our About Us page.

End-to-End Production Line Engineering

Installing a production line is not merely placing machines side-by-side; it is the realization of an efficiency algorithm. We design every stage of the process in-house. Our Siemens-based control systems maximize your line's OEE (Overall Equipment Effectiveness) while minimizing energy and time costs per part. Whether you need a comprehensive system or specific components like an Automated Sheet Metal Punching Line, our engineering adapts to your scale.

Sector-Specific Solutions

We focus our capabilities on niche sectors requiring global-standard expertise. We are a leading solution partner for the HVAC industry, specifically with our Dished Head Production Lines and specialized Casing Lines for Water Heaters.

In the automotive sector, we design complex systems for safety-critical components. Our Fuel Tank Production Line solutions demonstrate our ability to integrate deep drawing, welding, and testing into a seamless workflow.

Why Choose Emin Mekatronik Turnkey Solutions?

The cornerstones of the "Total Responsibility" model we offer to global investors include:

- Single Point of Accountability: We handle mechanics, Cutting and Forming Dies, and automation software in-house.

- Rapid Commissioning: The entire line undergoes rigorous testing at our facility before shipment.

- Flexibility: Our systems, such as the versatile EMK-850 Traffic Sign Machine, prove our ability to adapt automation to niche market needs.

Digital Transformation & Support

We equip our production systems with digital traceability infrastructure. This allows you to monitor performance and make data-driven decisions. For ongoing maintenance and technical assistance, our Service team ensures your lines maintain peak performance globally.

Emin Mekatronik is your strategic partner for new facility investments. You can explore our full range of capabilities in our Digital Catalog or see our proven track record on Our References page.

Ready to transform your factory into a technology base? Contact us immediately for a technical consultation and a custom quote.