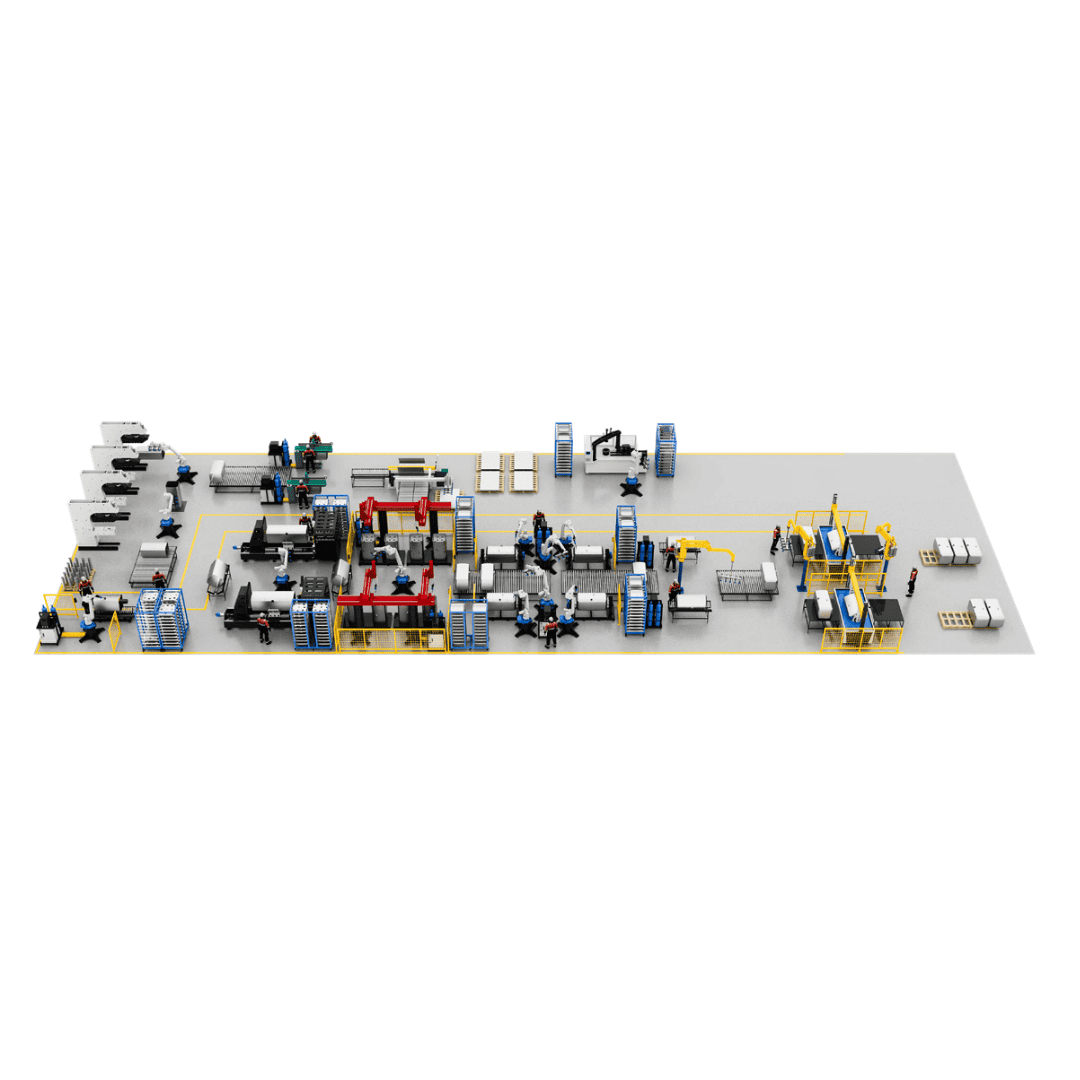

Specialized Automated Systems for the Automotive Industry

The modern automotive industry demands fuel tanks that are lightweight, exceptionally durable, and manufactured to the highest safety standards to ensure perfect, leak-proof integrity. Emin Mekatronik is a specialized engineering partner that designs and builds complete, automated production lines to meet these exact specifications.

Our core area of expertise is the setup of turnkey lines for aluminum fuel tanks, but our capabilities extend to all types of pressurized and non-pressurized hydro tanks made from aluminum, steel, and stainless steel. We plan and execute the entire manufacturing process, from raw material to the final tested product.

From Raw Material to Finished Tank: Our Integrated Process

We deliver a single, cohesive system where every stage is perfectly synchronized for maximum efficiency and quality. A typical production line includes:

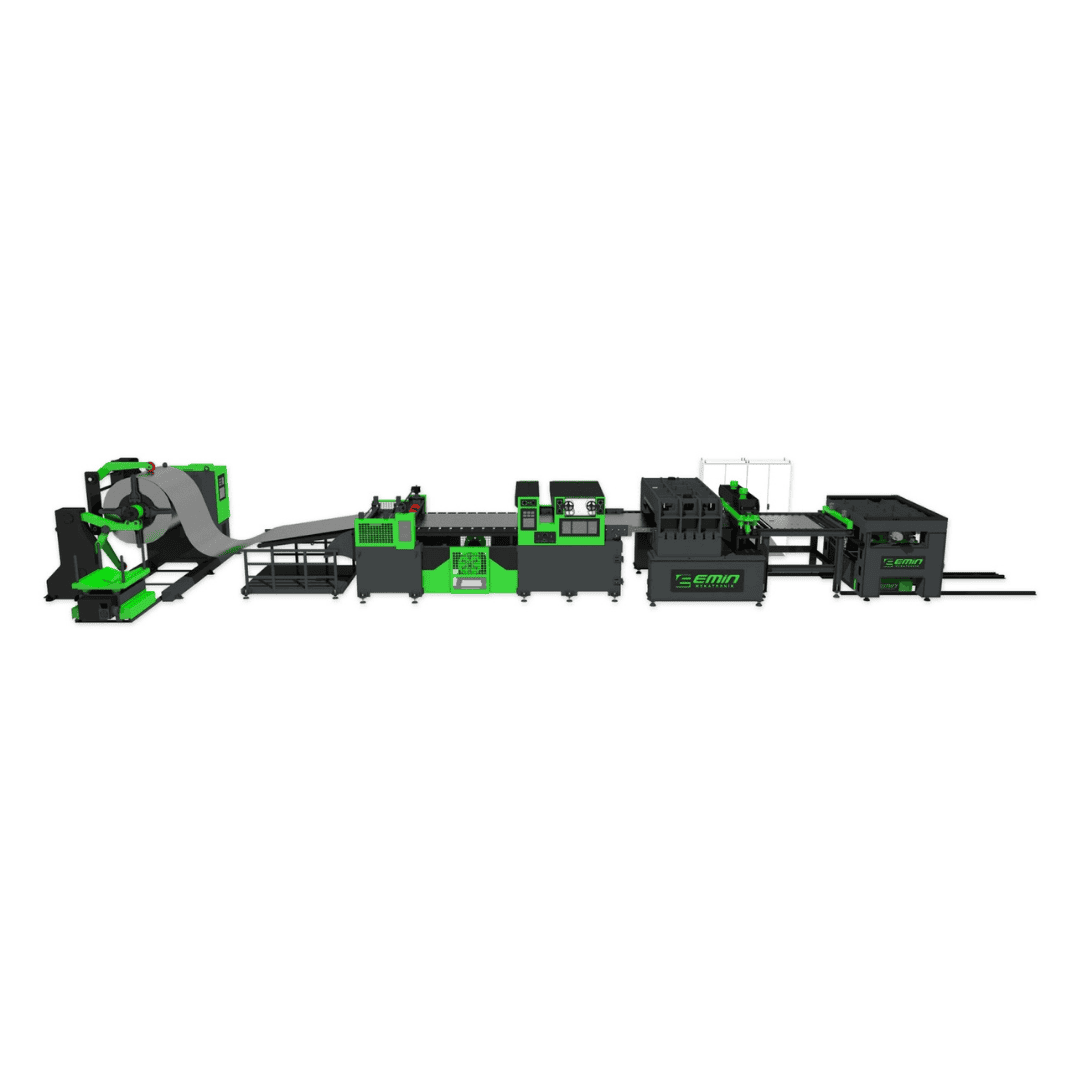

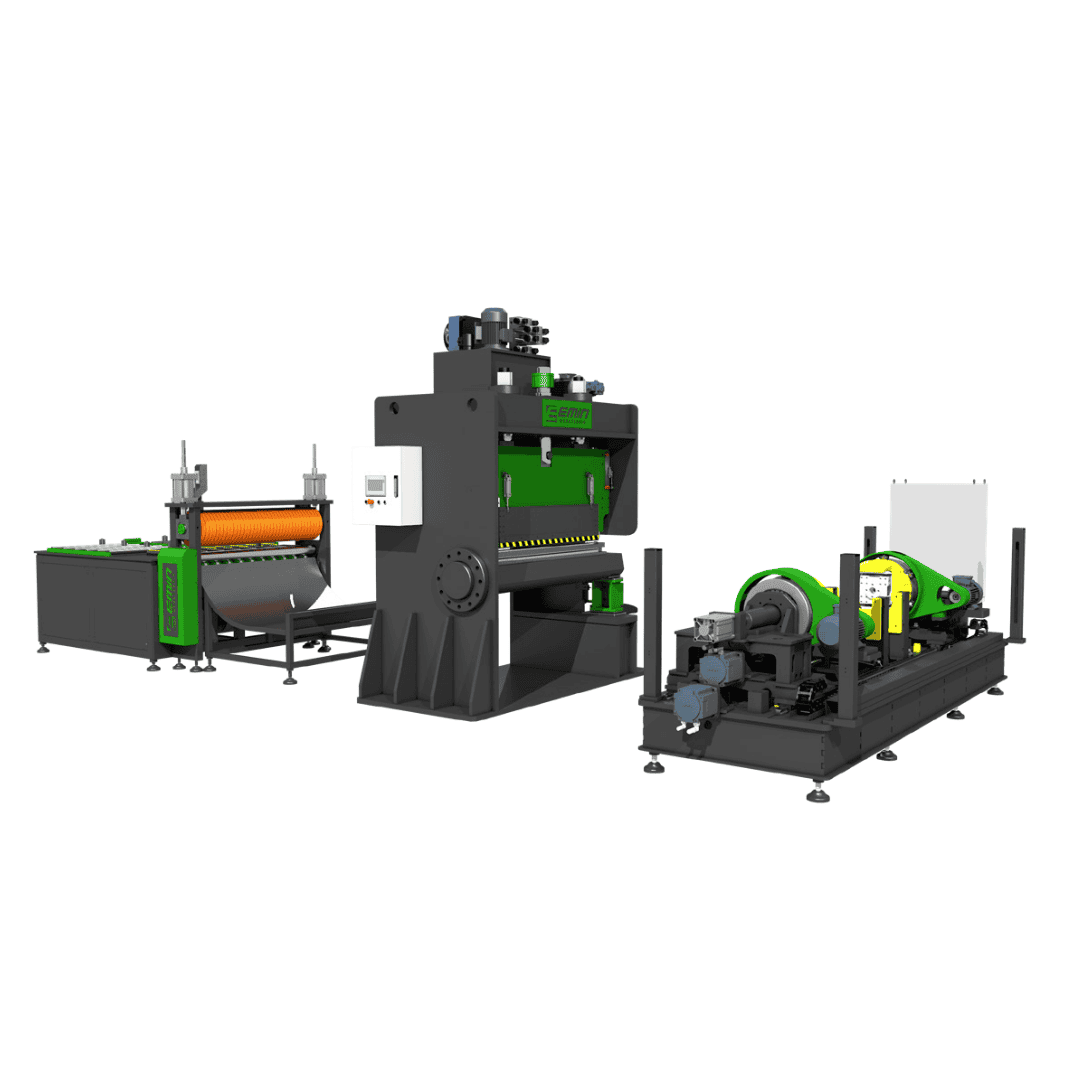

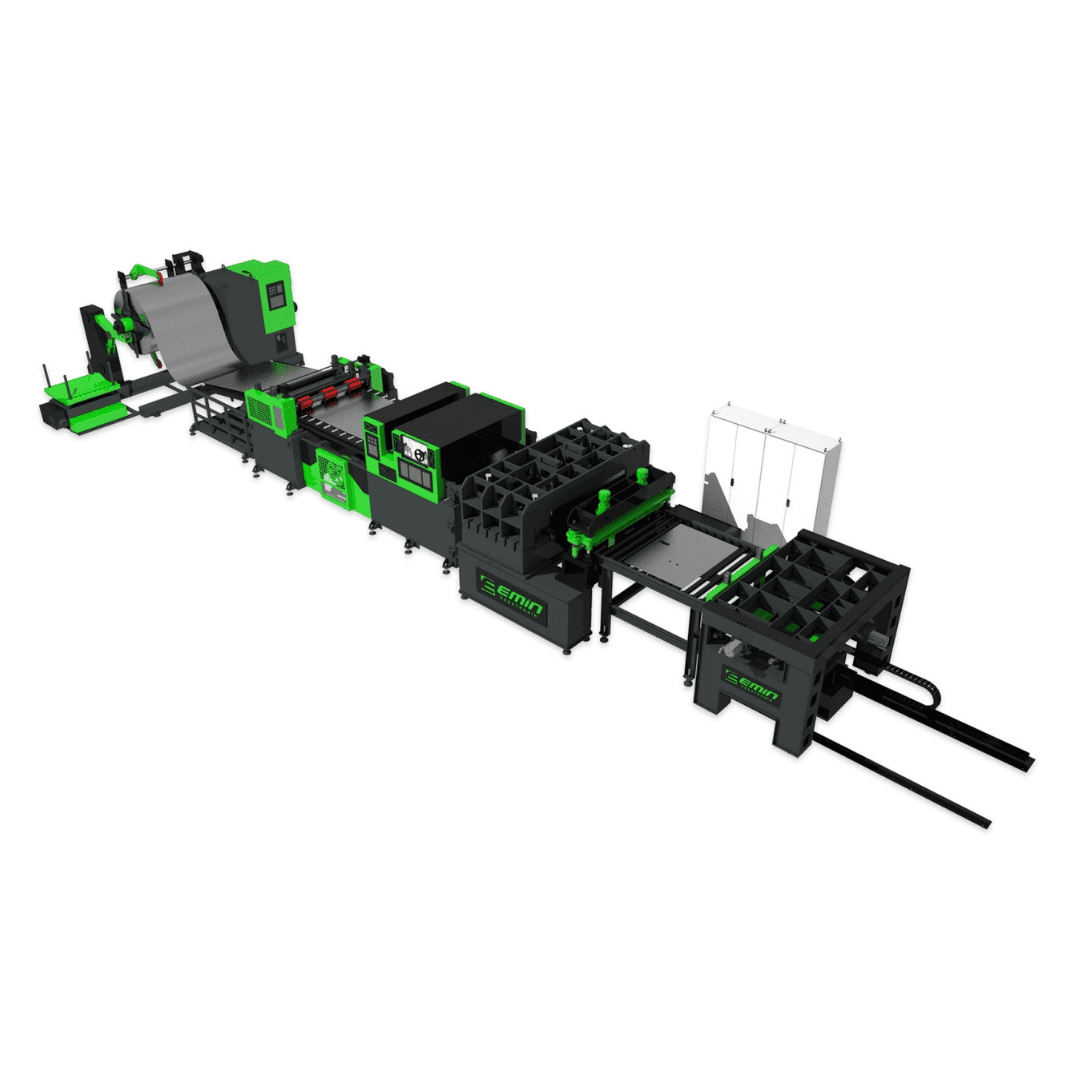

- Sheet Metal Preparation & Blanking The process begins with the automatic decoiling, straightening, and cutting of the sheet metal to create the precise blanks for the tank’s main shells and internal components.

- Stamping & Deep Drawing High-tonnage hydraulic or mechanical presses form the flat blanks into the complex geometries of the tank halves and internal baffles, which are critical for preventing fuel slosh.

- Robotic Welding & Seaming This is the most critical stage for tank integrity. Our lines integrate advanced robotic welding cells (MIG/MAG or TIG) to create strong, perfectly fused, and 100% leak-proof seams, ensuring the highest level of safety.

- Automated Component Assembly Dedicated stations automatically handle the precise installation of essential components such as filler necks, fuel pump mounts, sensor ports, and internal baffles.

- In-Line Leak Testing Quality is non-negotiable. Every single tank produced on our line is subjected to a mandatory, automated leak testing procedure. Tanks are pressurized and meticulously checked by sensitive sensors to guarantee they are perfectly sealed.

Key Features and Strategic Advantages

- Specialized Automotive Expertise: Our deep understanding of the automotive industry’s requirements for lightweight and durable aluminum fuel tanks ensures a compliant, efficient, and reliable solution.

- Multi-Material Capability: We have the flexibility to design lines that are optimized for aluminum, steel, or stainless steel, depending on your specific product requirements.

- Guaranteed Safety & Quality: The integration of robotic welding and mandatory 100% in-line leak testing ensures every tank that leaves the line meets the most stringent international safety standards.

- Complete Turnkey Solution: We manage the entire project lifecycle, from initial process planning and design to manufacturing, installation, and commissioning. This provides you with a single, expert point of responsibility.

Applications Beyond Automotive

The same robust engineering principles apply to a wide range of tank production needs:

- Hydraulic Oil Tanks for industrial machinery and mobile equipment

- Air Brake System Reservoirs for commercial vehicles

- Water and Utility Tanks for specialty vehicles (e.g., campers, RVs)

- Custom Small-Scale Pressure Vessels

Power your production with a fully automated, high-integrity tank manufacturing line. Contact our systems engineering team to discuss your specific requirements and to receive a detailed proposal.