Automated, Weld-Free Production for a Superior Finish

The outer casing of a boiler, water heater, or buffer tank is critical for aesthetics, structural protection, and the support of insulation. Producing these casings with a perfect cylindrical form, a clean and strong seam, and at high speed presents a significant manufacturing challenge.

Emin Mekatronik’s Sheet Metal Casing Line is a specialized, fully integrated solution designed to master this process. Our system utilizes an innovative weld-free joining technology to create high-quality casings, offering significant advantages in speed, finish quality, and operational cost over traditional welded methods.

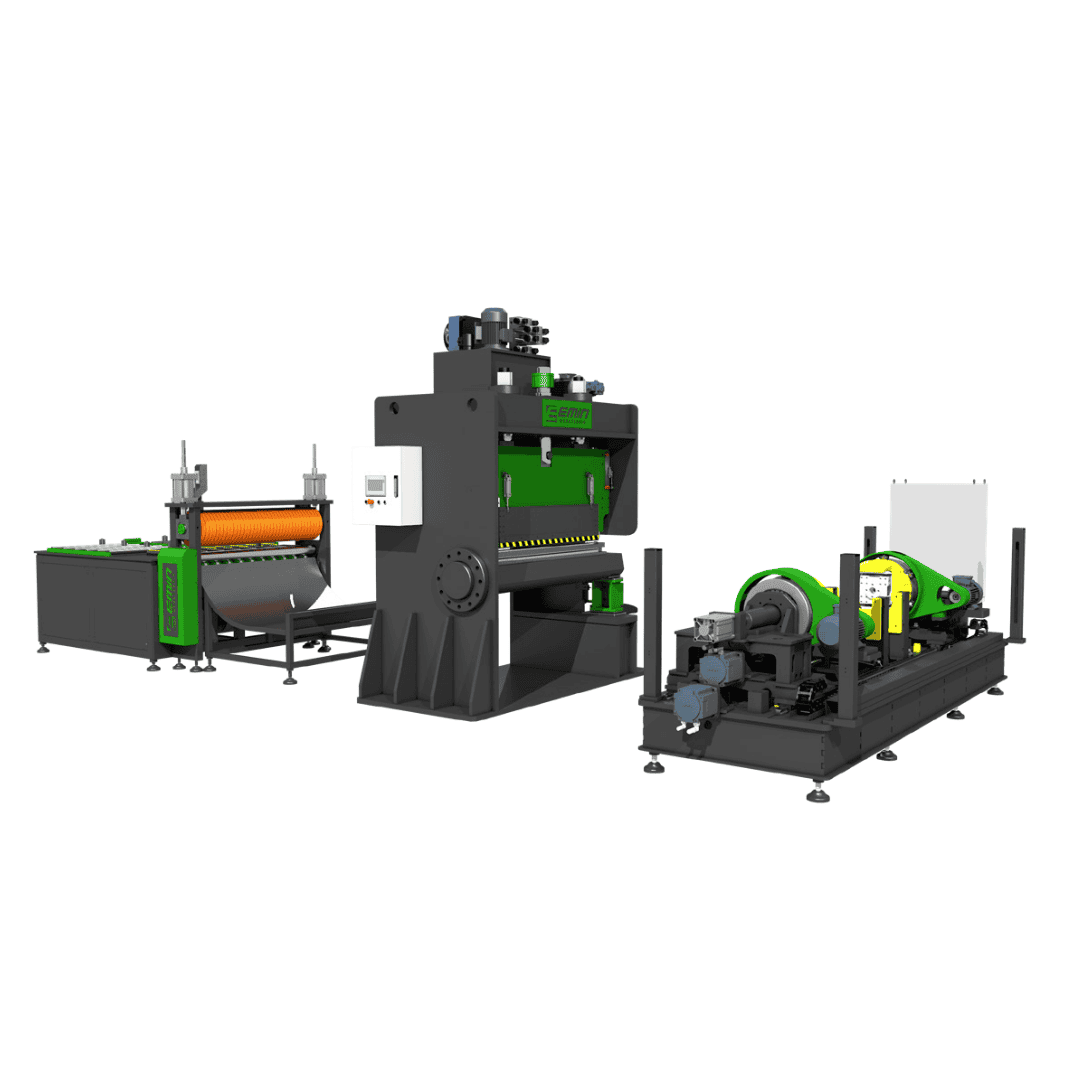

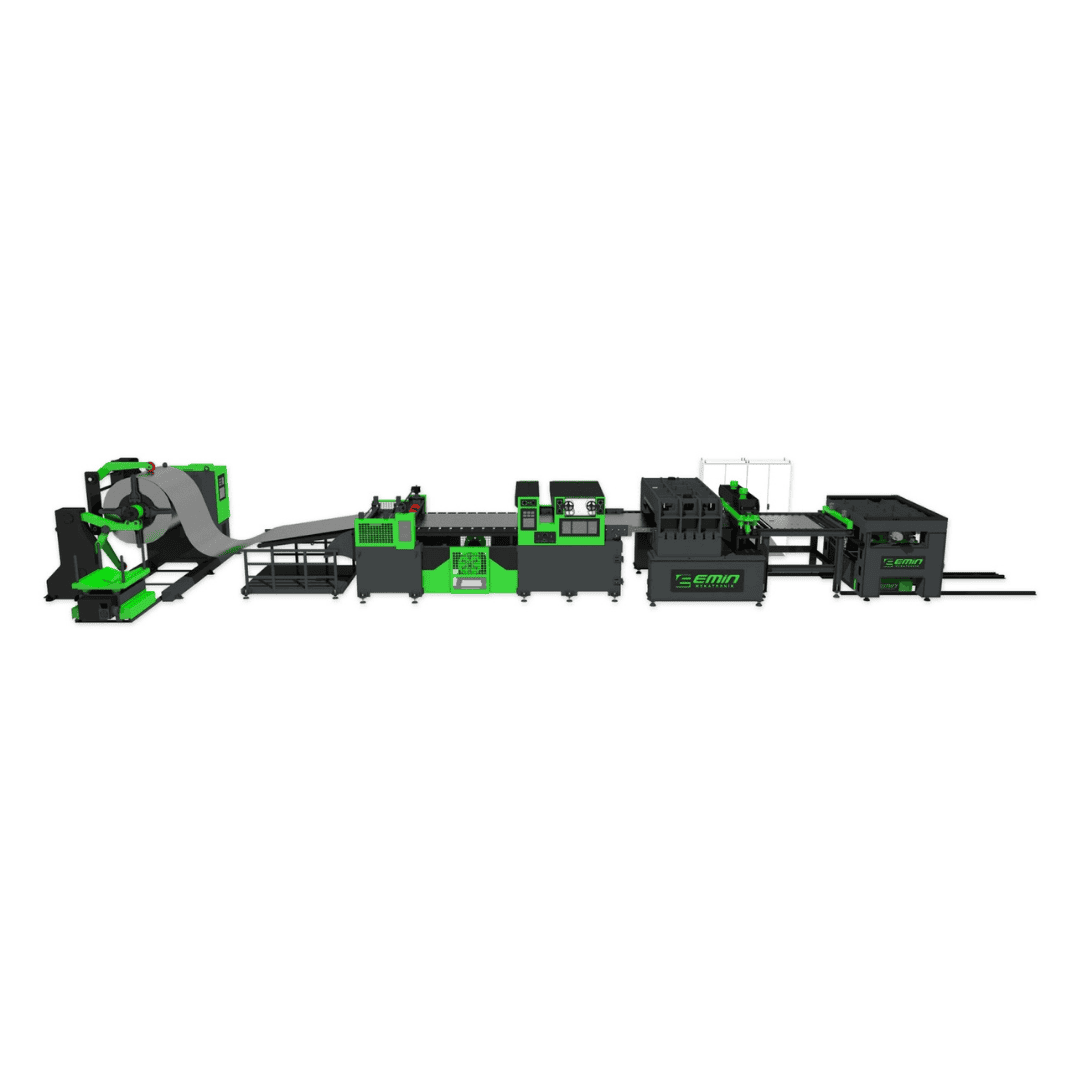

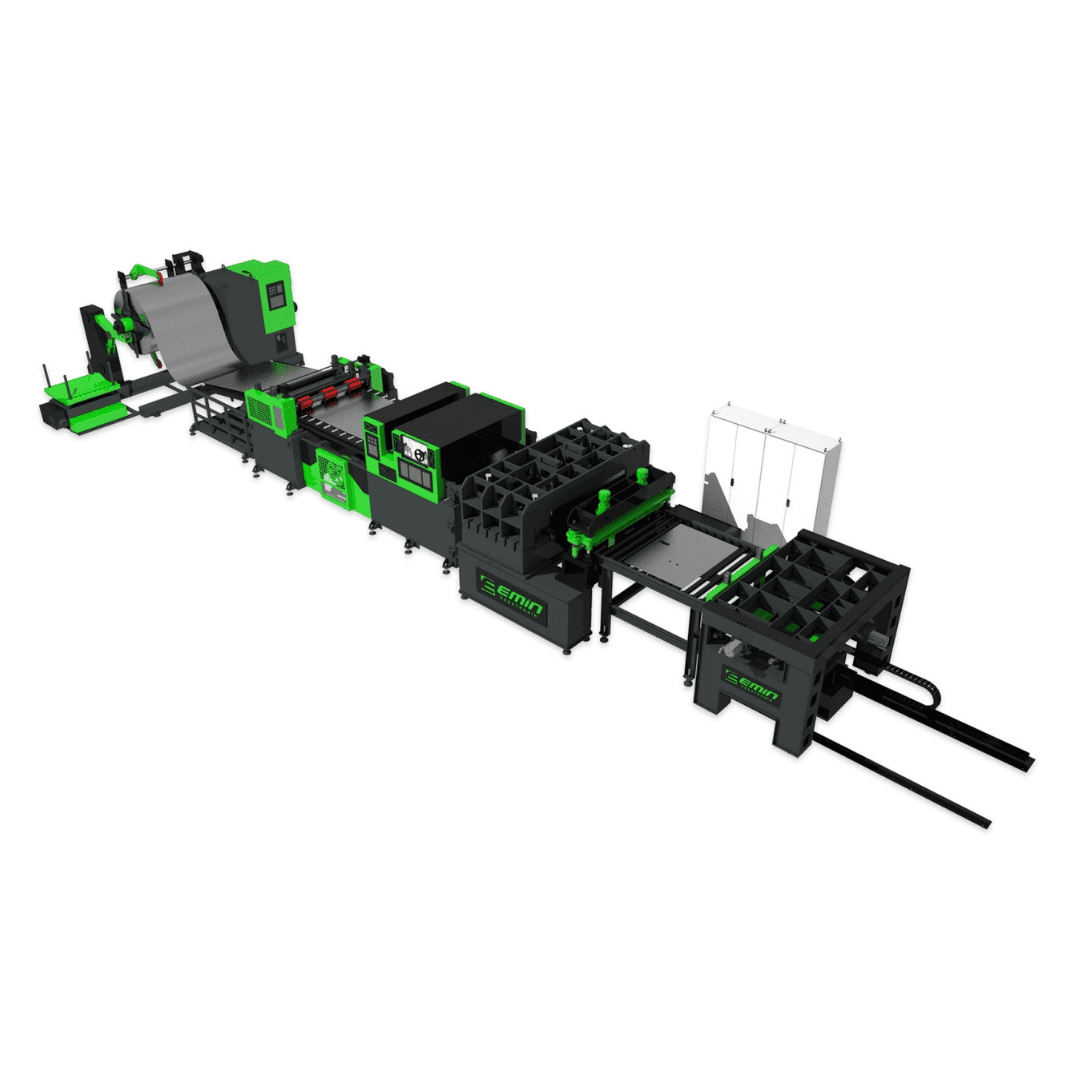

A Complete, Four-Stage Production Flow

Our line is engineered to transform flat sheet metal into a finished, ready-to-assemble casing in a single, automated flow. The process, explicitly designed without welding, includes:

1. Precision Cutting-to-Length The line can be fed with pre-cut blanks or integrated directly with a cut-to-length system processing from a coil. The sheet is cut to the exact circumferential length required for a perfect fit.

2. High-Accuracy Roll Bending The flat sheet is then fed into a precision multi-roll bending machine. This station forms the sheet into a perfect cylinder with consistent curvature along its entire length, ensuring a high-quality final appearance.

3. Innovative Mechanical Joining (Weld-Free) The key advantage of our line lies in its innovative mechanical joining system. Instead of welding, the line uses a high-force seaming or clinching process to lock the two ends of the sheet together. This weld-free method offers superior benefits:

- Perfect for Pre-Painted Materials: No heat means no damage to paint, vinyl, or other coatings, allowing you to use pre-finished materials and eliminate post-production painting.

- Higher Production Speed: Mechanical joining is significantly faster than a welding cycle.

- Superior Aesthetic Finish: The process creates a clean, uniform seam with no weld marks, spatter, or discoloration, eliminating the need for costly post-weld grinding and cleaning.

4. Edge Forming (Inward Bending / Beading) In the final automated stage, the top and bottom edges of the cylindrical casing are formed. This “inward bending” or “beading” process creates a clean, reinforced edge, preparing the casing for a perfect assembly with the tank’s dished heads or end caps.

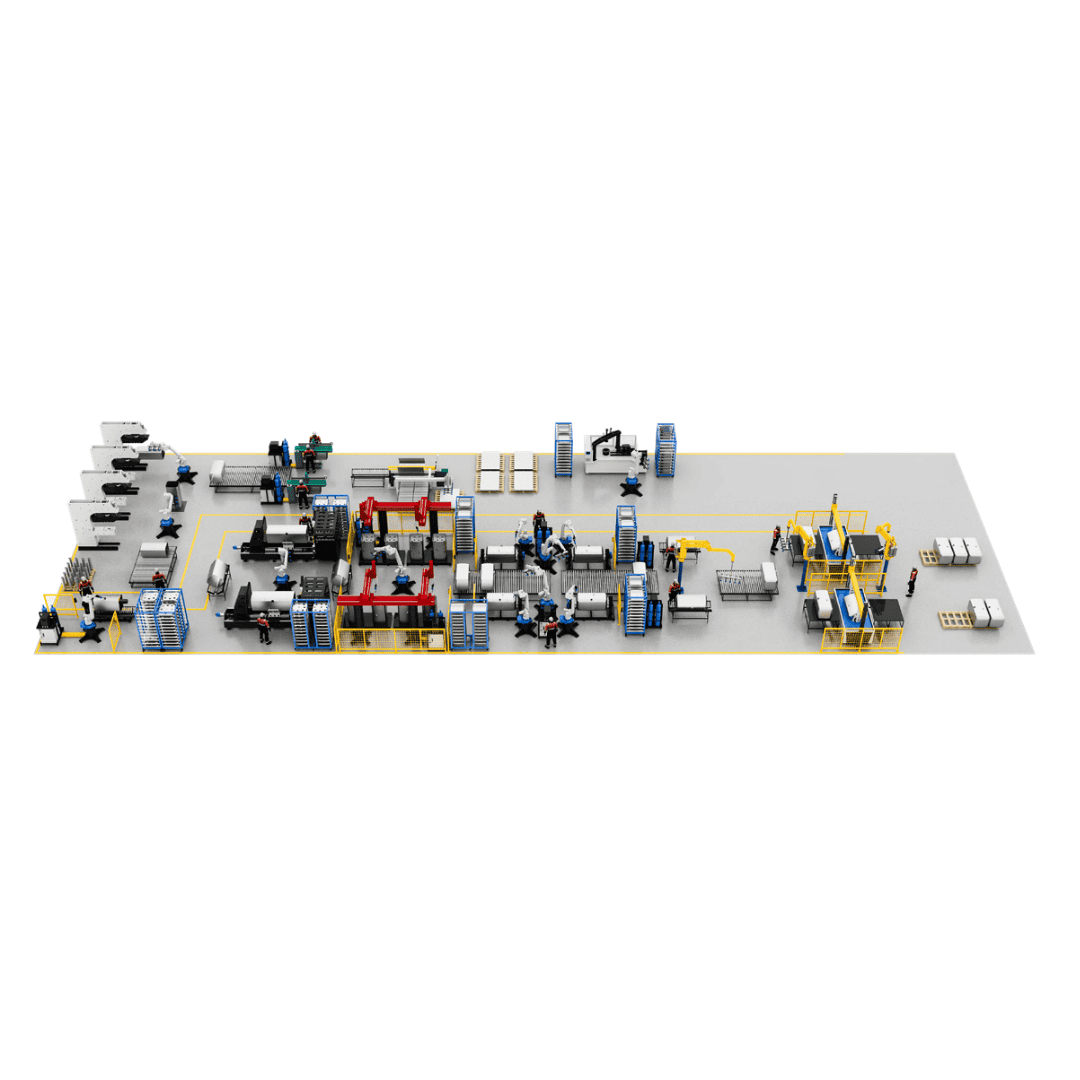

Key Features and Strategic Advantages

- Superior Aesthetic Quality: The clean, weld-free seam provides a modern, high-end look perfect for consumer-facing products.

- High-Speed, Continuous Production: The entire process is designed for the high-throughput manufacturing of boiler and tank casings.

- Lower Operational Costs: Eliminates the need for welding consumables, gases, specialized welding operators, and secondary grinding operations.

- Turnkey Integrated Solution: We design the complete line to work as a single, synchronized system, providing you with a reliable and fully tested manufacturing solution.

Primary Applications

- Outer Casings / Jackets for Hot Water Boilers

- Protective Shells for Buffer and Accumulation Tanks

- Cylindrical Housings for HVAC Equipment

- Large Diameter Ducting and Industrial Silencers

- Barrels and Drum Bodies

Elevate the quality and efficiency of your tank and vessel manufacturing. Contact our engineering team to learn more about our innovative, weld-free Sheet Metal Casing Line.