Turnkey Automated Production Systems: Engineering the Future

At Emin Mekatronik, we are more than machine builders; we are your end-to-end solution partner for the design, manufacturing, and implementation of turnkey automated production systems. Since 2009, our expertise has lay in transforming unique industrial challenges into integrated, high-efficiency custom machinery. From initial concept to final commissioning, we deliver complete production lines built to perform, scale, and provide a decisive competitive edge.

Overcoming Modern Manufacturing Challenges

In today's global market, manufacturers face immense pressure to increase output while controlling operational expenses. Standard equipment often fails to address the nuances of specialized processes. Our automated production systems provide a definitive solution by replacing inefficient manual tasks with precision robotics and Siemens-powered automation. This ensures higher throughput, flawless quality, and a safer manufacturing environment.

Custom Machinery Engineering: Our Core Competency

We believe effective automation is not one-size-fits-all. Our process begins with a deep dive into your workflow and long-term goals. Our in-house team utilizes advanced 3D CAD/CAE software—including CATIA, SOLIDWORKS, and VISI—to design custom machinery from the ground up. This ensures every robotic arm and line of code is perfectly optimized for its intended task, maximizing your Overall Equipment Effectiveness (OEE).

Your End-to-End Solution Partner

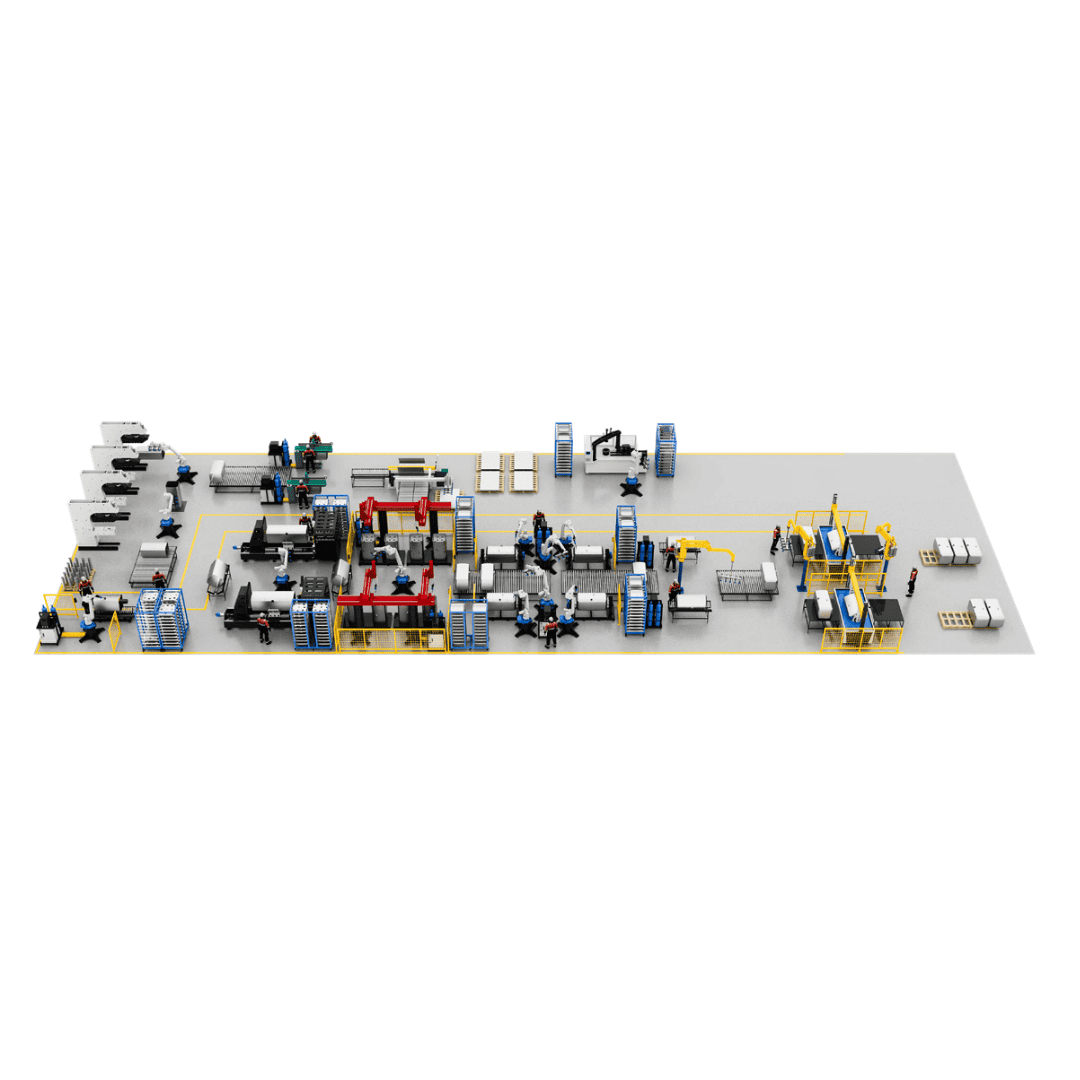

Choosing Emin Mekatronik means choosing accountability. Our turnkey approach covers every stage of the project lifecycle:

- Consultation & Analysis: Defining the project scope and technical requirements.

- System Design & Simulation: Validating designs via kinematic analysis before any metal is cut.

- In-House Manufacturing: All critical components are assembled at our state-of-the-art facility in Kayseri, Turkey.

- Integration & Programming: Experts integrate mechanical systems with advanced Siemens Motion Control.

- Installation & Commissioning: On-site setup and fine-tuning until performance benchmarks are exceeded.

- Training & Support: Comprehensive operator training to ensure maximum uptime.

Specialized Production Line Expertise

We have cultivated deep, industry-leading expertise in several key manufacturing sectors:

Advanced Fuel Tank Production Lines

For the automotive industry, we design complete lines for aluminum, steel, and stainless steel fuel tanks. Our systems manage the entire process, including deep drawing, CNC trimming, robotic welding (MIG/TIG/Laser), and automated leak testing.

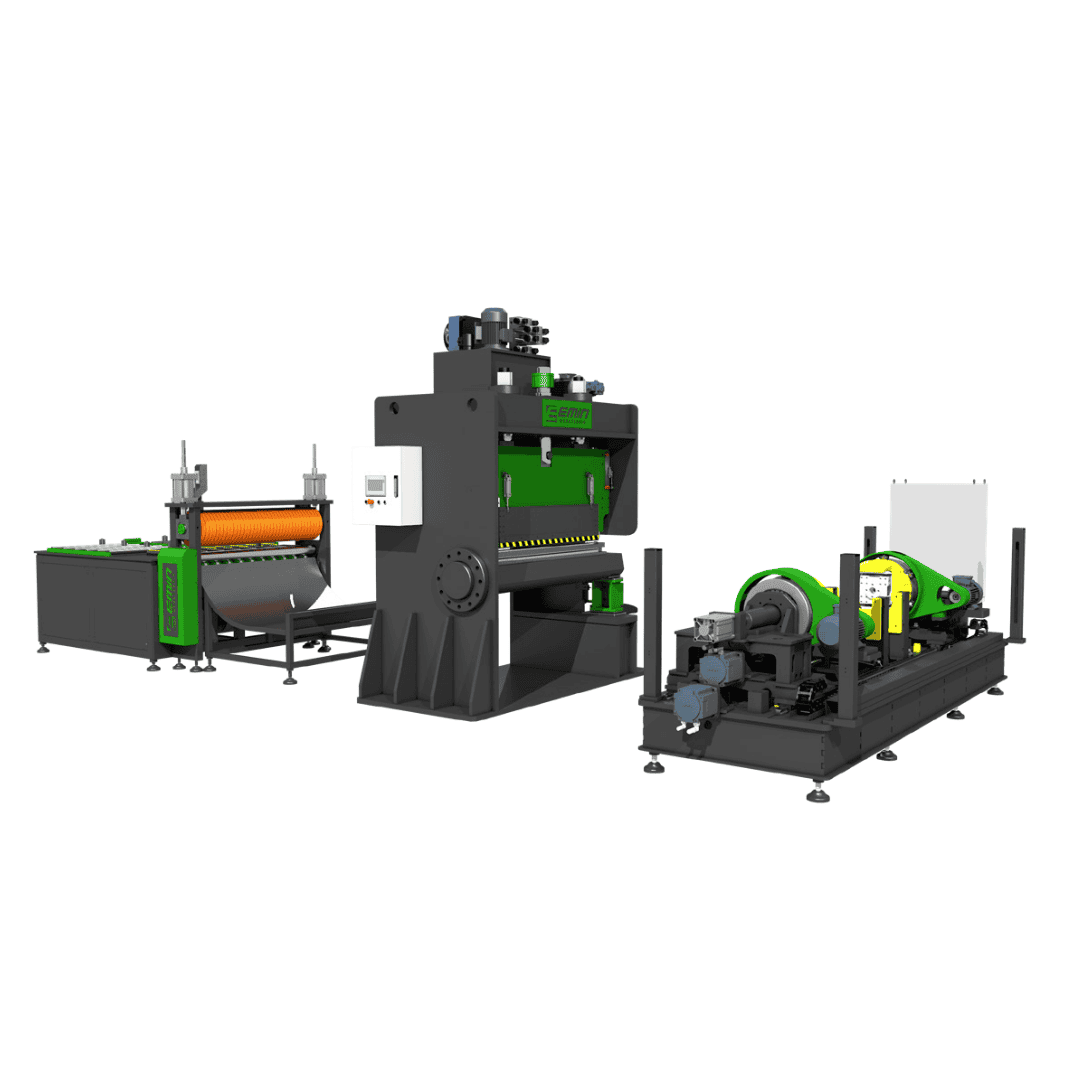

Boiler and Water Heater Production Technology

Manufacturing pressure vessels requires extreme accuracy. We offer specialized lines for dished head production, welding-free outer body sac processing, and automated coating lines.

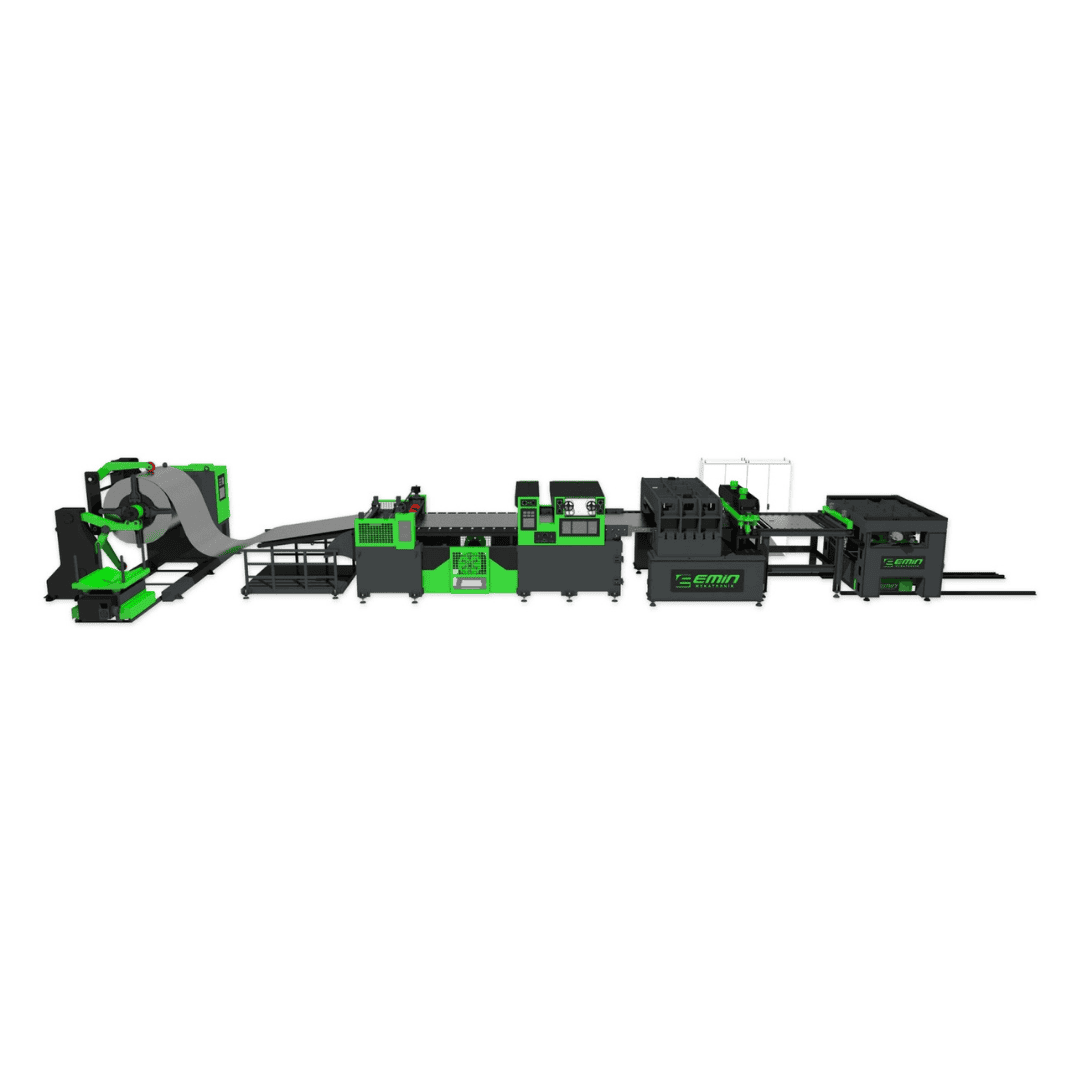

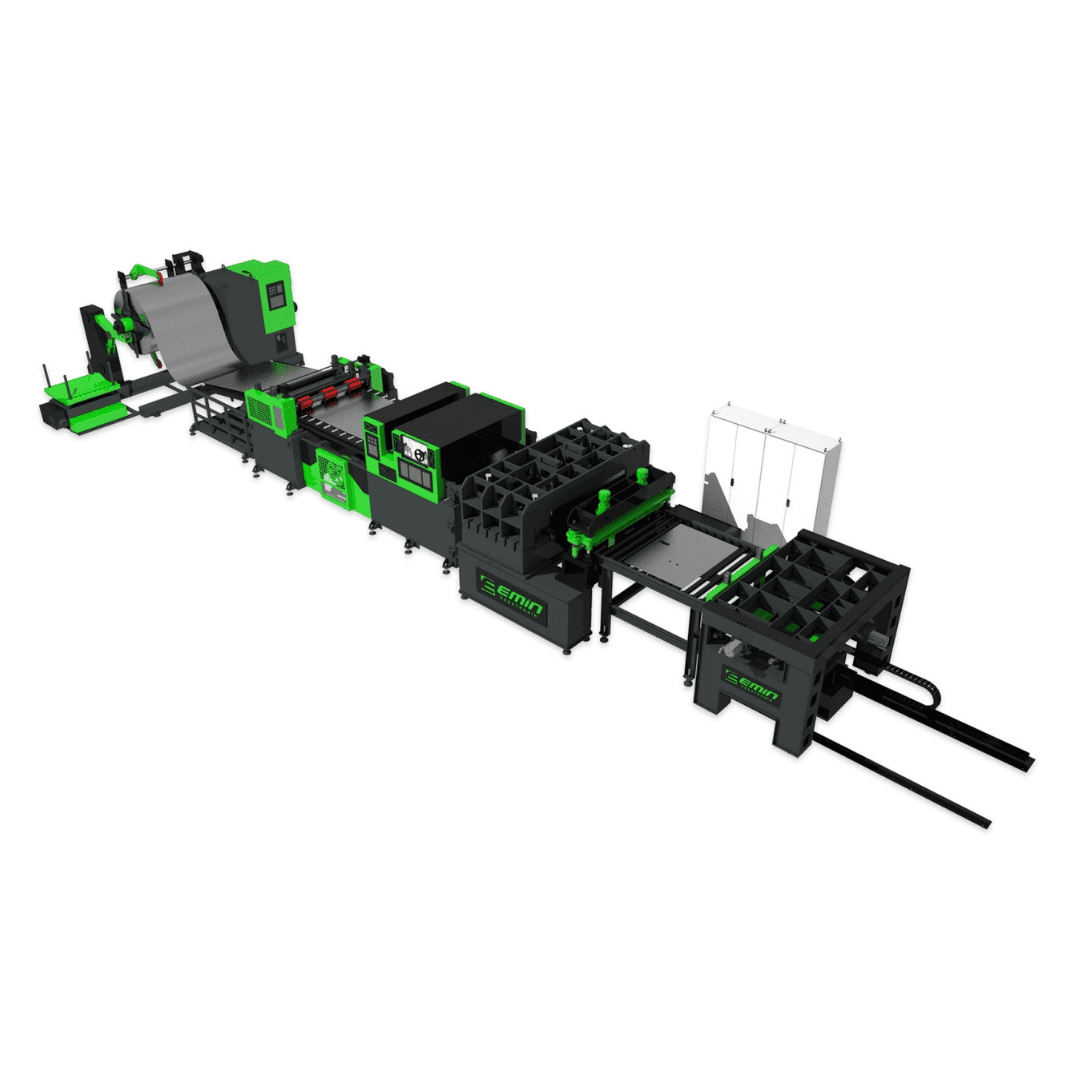

Rulo Punch & Automated Slitting Lines

Our integrated Rulo Punch and Boy Kesme lines automate decoiling, straightening, and high-speed punching for appliance and industrial casings.

The Emin Mekatronik Advantage

- 15+ Years of Excellence: A long history of successful industrial projects since 2009.

- Fully Integrated Design: Every part of the system—from mechanical design to automation software—is handled 100% in-house.

- Global Standards: All machinery is built to international quality and CE safety standards.